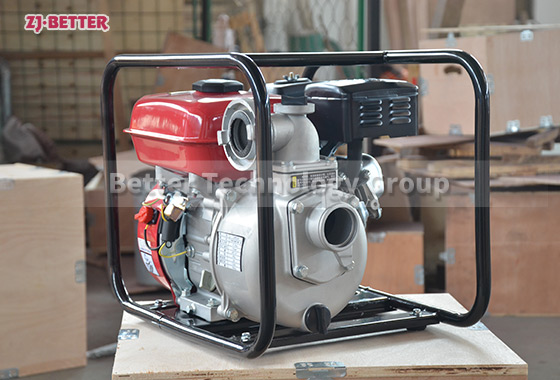

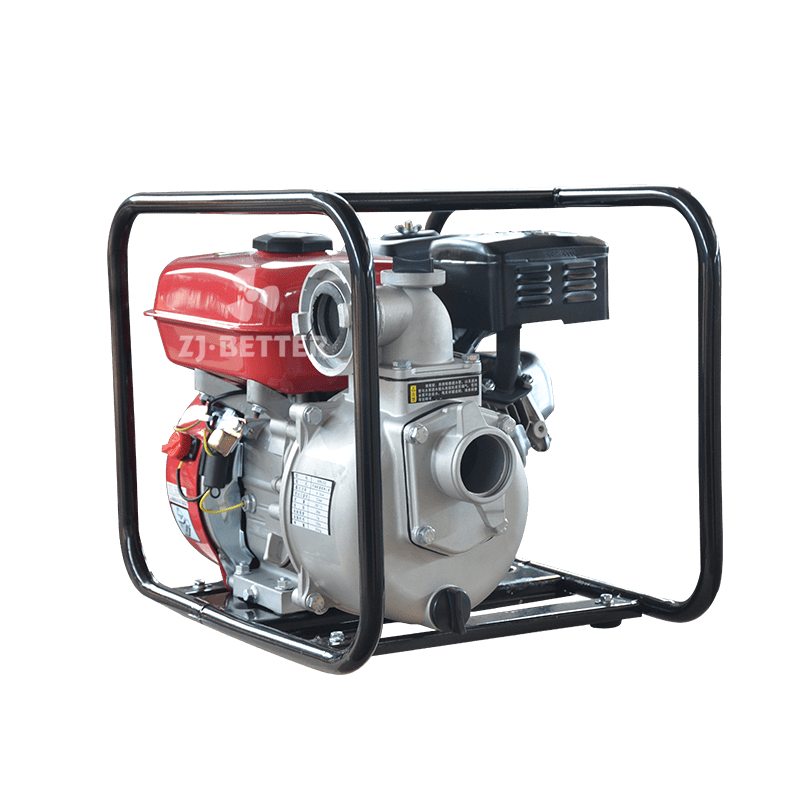

Portable fire pump

Portable pump, mostly used for irrigation and port dock pumping water. Is a small diesel pump, now many countries began to use a large range of portable diesel pump, because the diesel pump is not affected by the power system, can work in an electric environment, and portable diesel pump is easy to install and move, is favored by the majority of customers.

Better (China) Technology Co,Ltd.was founded in 2004.We are

locate in Hangbu development zone,Quzhou,Zhejiangwith convenient

transportation access, covering an area of 20000 square meters,for

15000 square meters workshop. It combines the functions of professional

design, development,manufacture and sale of general fluid equipment of high-tech enterprise. It has established the technology cooperation with overseas famous companies such as Hyundai Pump Corp. of Korea

Sitian Corp. of Japan etc introduced the advanced designdevelopment

and management mode, and long employed foreign expert as the instructor. The products enjoy the competitive force in global market. Better Pump has established many sales distributions and agencies

in the major provinces in China.Through attending a variety oflarge

scale exhibition, we have developed a broader market.We are looking forward to forming successful business relationships with new clients

around the world in the near future.