How to choose the right fire pump for you?

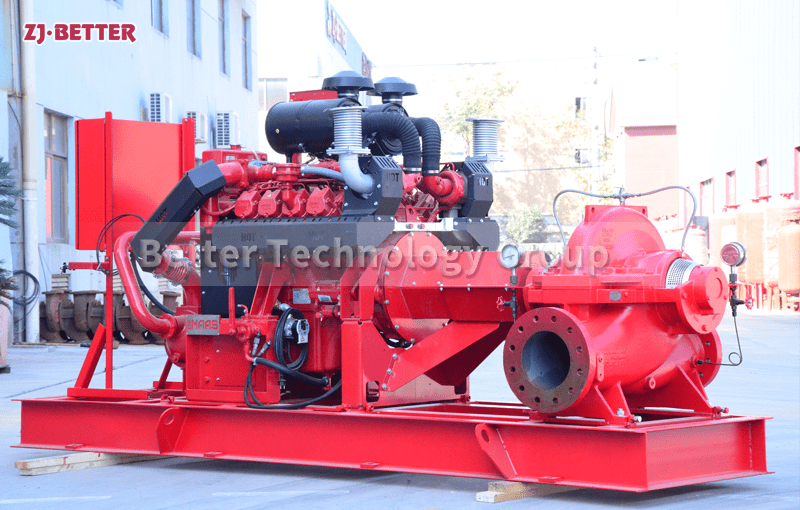

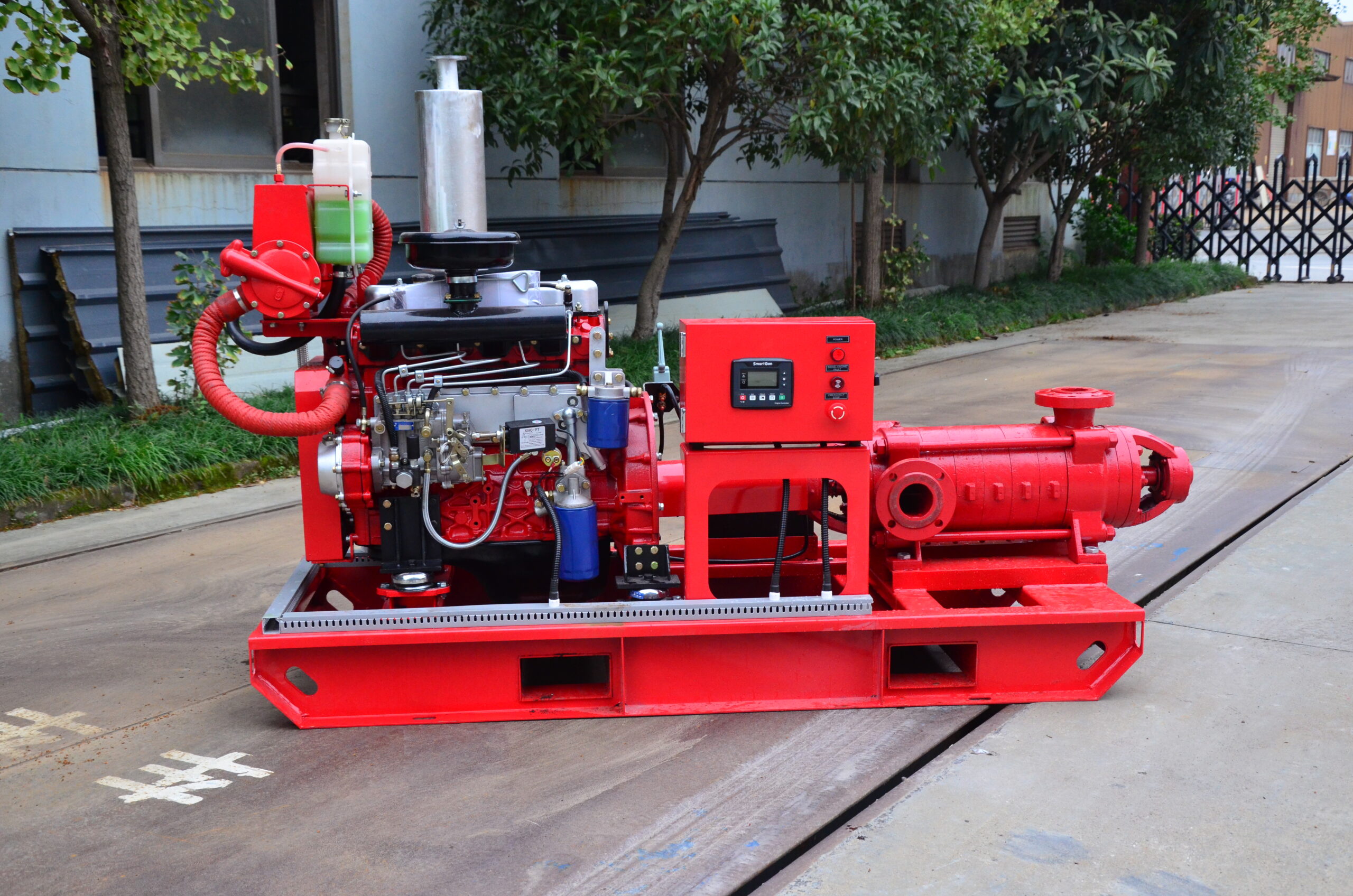

The fire pump is suitable for pressurizing water supply in the fire pipeline. The purpose is to transport clean water or other liquids with physical and chemical properties similar to clean water for pressurization. The temperature of the medium used by the horizontal pump is not higher than 80 °C, which is suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, long-distance water supply, heating, bathroom and other cold and warm water circulation pressurization and equipment matching.

1. Selection of liquid flow rate for fire pump delivery

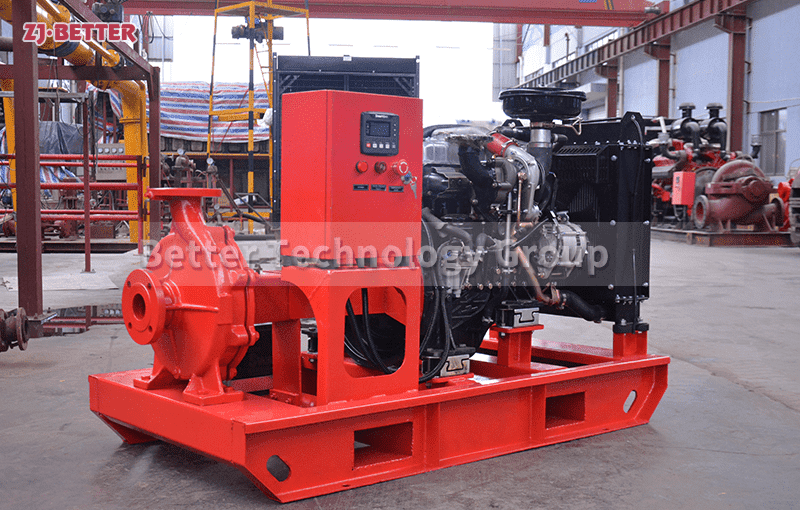

Among the many functions of the fire pump, the transport of liquid is one of the most critical functions, so the flow rate of the liquid that the fire pump can transport determines the working capacity of the fire pump. Therefore, the flow rate of the conveyed liquid determines the working efficiency of the fire pump. 2. Choose a fire pump according to the location

Since there are many classifications of fire pumps according to the occasion of use, in the selection process, the selection must be made according to the occasions where the buyer needs to use the fire pump, so that the working capacity of the fire pump can be improved.

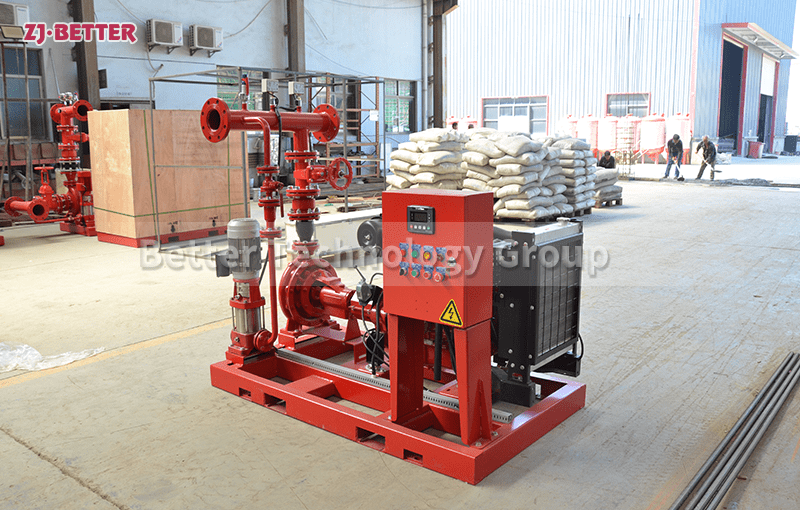

3. Choose a qualified fire pump

Fire pumps are a key part of fire protection facilities, so the country will have corresponding regulations for the production and sales of fire pumps. Qualified fire pumps will only be certified by the national fire equipment supervision and inspection agency before leaving the factory. Therefore, when choosing a fire pump Pay attention to the inspection certificate when purchasing, so as to ensure that the buyer can buy a fire pump with excellent quality.