Composition and application of fire pump group diesel engine fire pump group

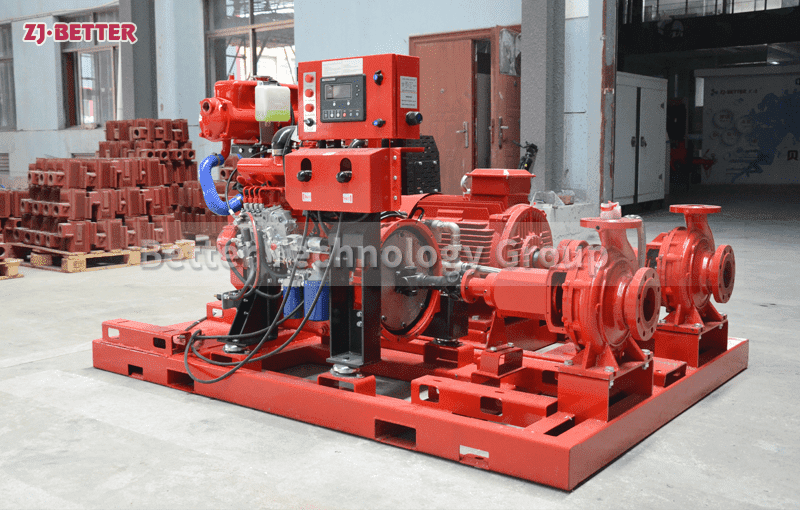

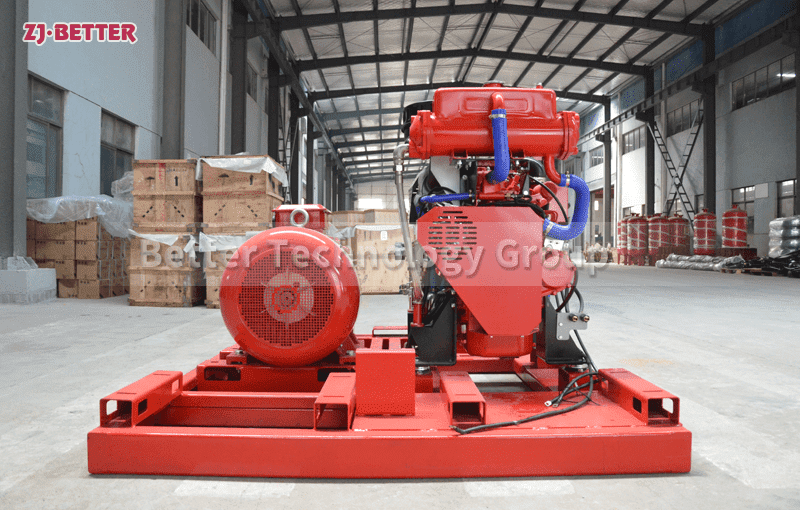

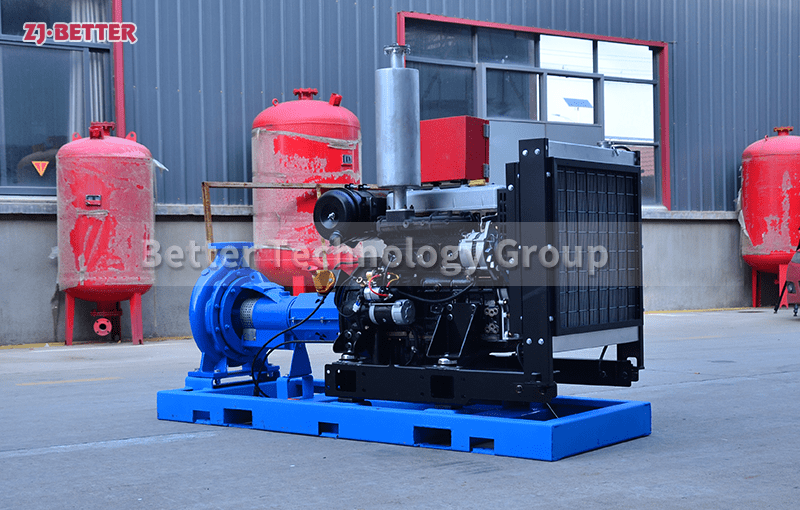

Diesel engine fire pump group consists of water pump, diesel engine, electrical instruments and other equipment, which are tightly installed on a common chassis, and connected with the electric control box through control lines and signal lines. The complete set of diesel engine water supply equipment can be used for automatic/manual production of various enterprises. The water supply system can also be used for fire water supply and occasions with special requirements.

Diesel engine fire pump is a kind of electromechanical integrated equipment that is directly driven by fire pump and can start and complete water supply in a short period of time. The pump set is driven by diesel and does not need an external power supply. It is suitable for various fire water supply occasions such as agricultural irrigation, emergency rescue, smelting, hangars, petrochemical oil depots, liquefied gas stations, and textiles. Especially when the power supply is not satisfactory, diesel engines are used. Driving water pumps is a reliable and guaranteed equipment choice.