In today’s safety-critical infrastructures – be it high-rise buildings, manufacturing facilities, or petrochemical sites – a dependable fire protection system is no longer optional. It’s essential. While electric fire pumps perform well under normal conditions, their reliance on external power sources becomes a liability during blackouts, natural disasters, or electrical faults. The diesel engine-driven fire pump is specifically engineered to eliminate this risk by providing a self-contained, high-performance emergency firefighting solution.

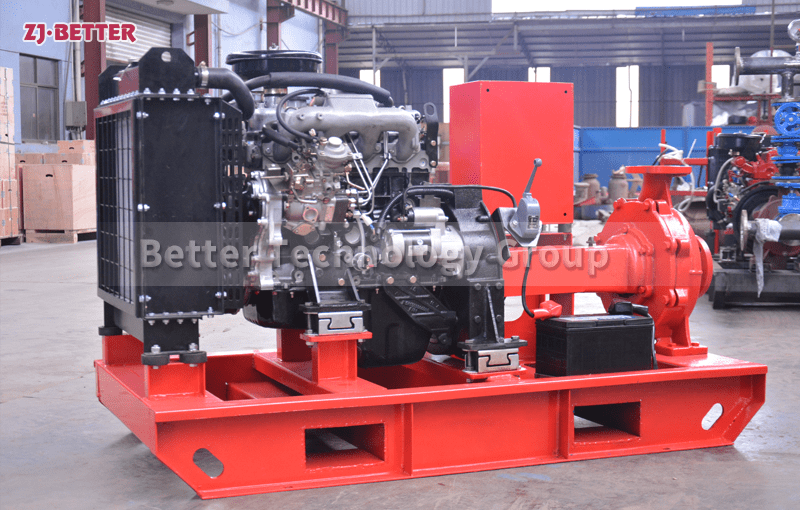

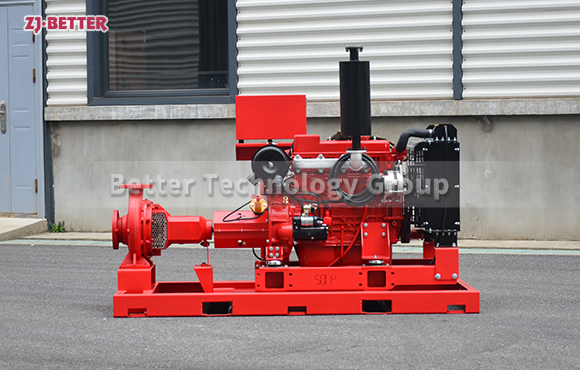

This diesel fire pump set features an industrial-grade diesel engine paired with either a horizontal split-case pump or end-suction pump. Designed for high-volume flow and high head applications, the unit guarantees uninterrupted water delivery even in the harshest conditions. With an intelligent PLC control panel, operators gain full control over automated start/stop, fault alarms, remote diagnostics, and real-time monitoring – a complete solution for mission-critical environments.

Key Technical and Functional Advantages:

-

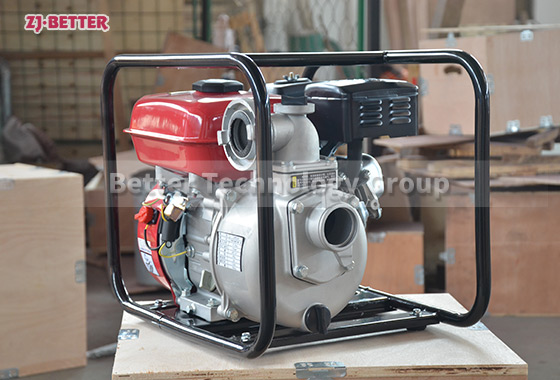

Self-Reliant Power Source: Operates independently of grid power, ideal for off-grid, remote, or blackout-prone areas.

-

Premium Diesel Engine: Equipped with world-class engine brands such as Cummins, Weichai, or Yuchai – known for fast start, durability, and low emissions.

-

Hydraulically Optimized Pump Design: High-efficiency impellers and robust construction enable both high-pressure and high-flow applications.

-

Advanced Smart Control: Features PLC-based logic for automatic operations, real-time diagnostics, and multi-signal alerts (e.g., low fuel pressure, overheat protection).

-

Skid-Mounted Integration: Fully pre-assembled for easy on-site installation with compact footprint and reduced commissioning time.

-

Corrosion-Resistant Materials: Key components made from cast iron, stainless steel, or bronze for long-term operation in various water qualities.

-

Rigorous Quality Testing: All units undergo strict hydraulic testing, performance validation, and engine-pump synchronization before dispatch.

-

Fuel Efficiency Design: Delivers maximum hydraulic output with optimized fuel usage, minimizing operational expenses.

-

Certified to Global Standards: Available with NFPA20, UL, ISO compliance, making it suitable for international fire protection projects.

-

Fully Customizable Options: Tailored configurations based on required flow rate, head, site conditions, and fire safety standards.

The diesel fire pump is more than a backup – it’s a proactive safety investment. Whether used as a primary solution in off-grid areas or as a secondary failsafe in critical infrastructure, it offers unmatched performance, autonomy, and reliability.