Optimal Performance Choice:Diesel Vertical Turbine Fire Pump

Flow:50-7500 GPM

Head:3-20 Bar

Power:11-1000 kw

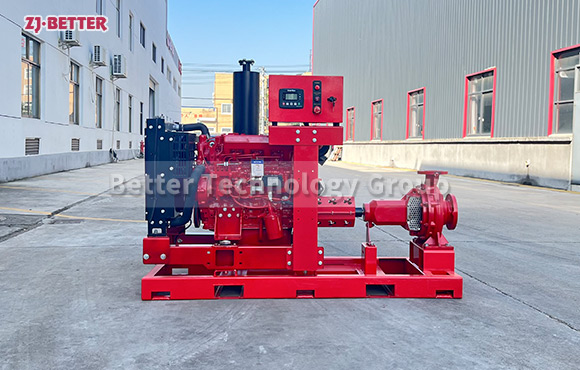

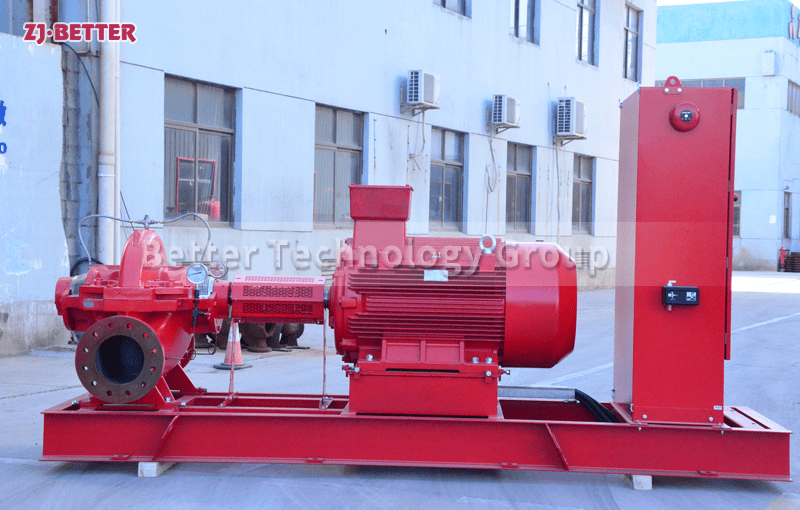

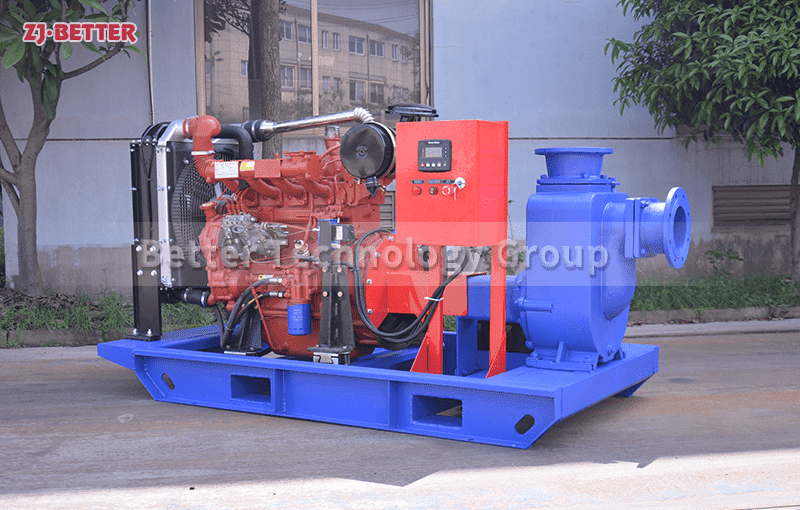

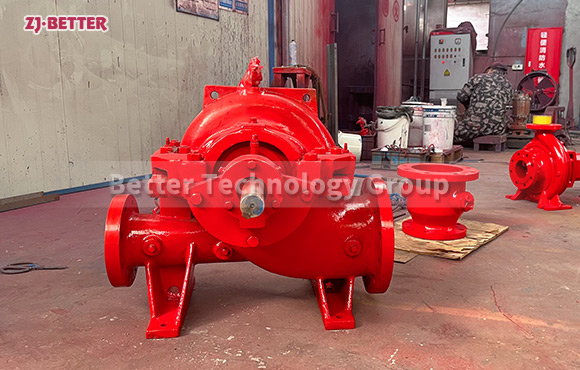

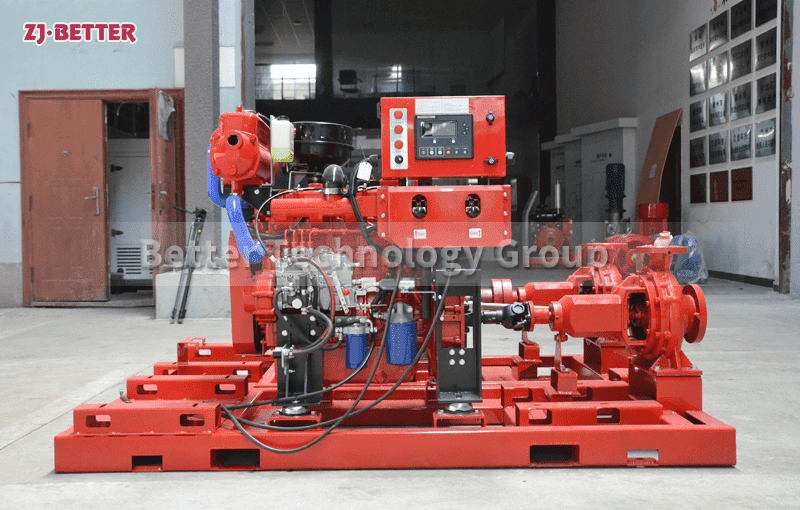

The XBC-JC Diesel Engine Vertical Turbine Fire Pump is a reliable and efficient hydraulic solution designed for extracting water from deep wells and hot springs. With its unique long shaft design and advanced technology, this pump delivers powerful pumping capacity and lift height, swiftly transporting large volumes of water to desired locations.

The XBC-JC Diesel Engine Driven Vertical Turbine Fire Pump excels in extracting water from deep wells, rivers, lakes, and seas, whether it’s for obtaining ambient temperature firefighting water or hot springs below 100 degrees Celsius. With its powerful pumping capacity and lift height, this long shaft pump swiftly and effectively delivers a large volume of water to the desired location.

Featuring a compact structure due to its long shaft design, this pump is suitable for complex working environments. Whether used in construction sites or agricultural irrigation, the XBC-JC Diesel Engine Driven Vertical Turbine Fire Pump reliably provides the required hydraulic support. Additionally, it comes equipped with an automatic start-stop function to intelligently control the pump’s operation, saving energy and maintenance costs.

The XBC-JC Diesel Engine Driven Vertical Turbine Fire Pump has a wide range of applications, making it suitable for extracting water from deep wells and hot springs. Whether it’s for firefighting, urban water supply systems, or hot spring facilities, it delivers reliable hydraulic support, ensuring smooth operations.By choosing the XBC-JC Diesel Engine Driven Vertical Turbine Fire Pump, you gain a trustworthy equipment that guarantees efficient extraction of water from deep wells and hot springs. We are committed to providing excellent hydraulic solutions to enhance your work efficiency and safety.