Diesel Engine Fire Pump Set Installation Instructions

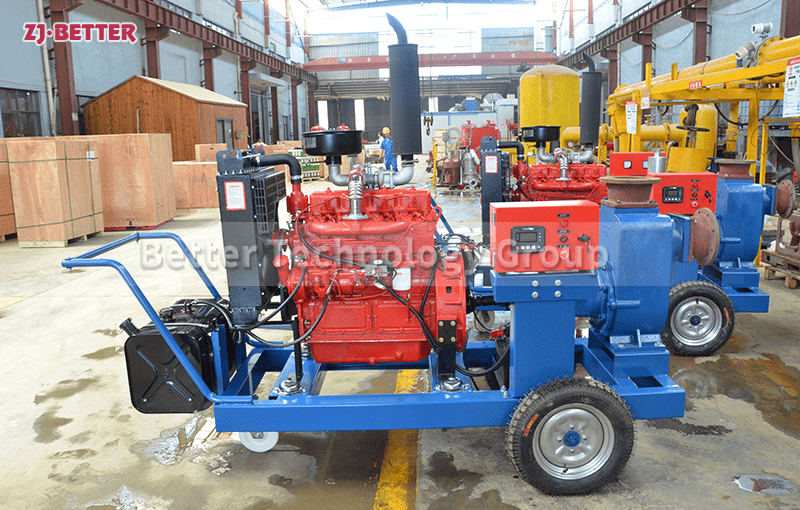

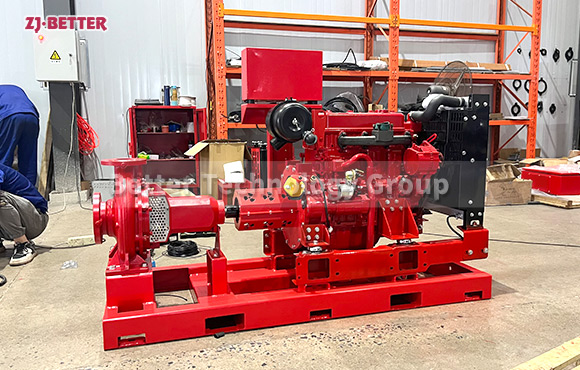

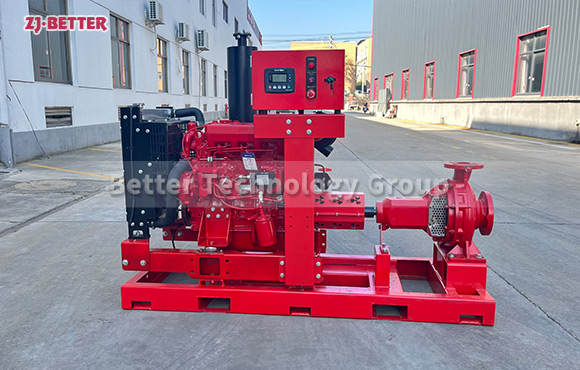

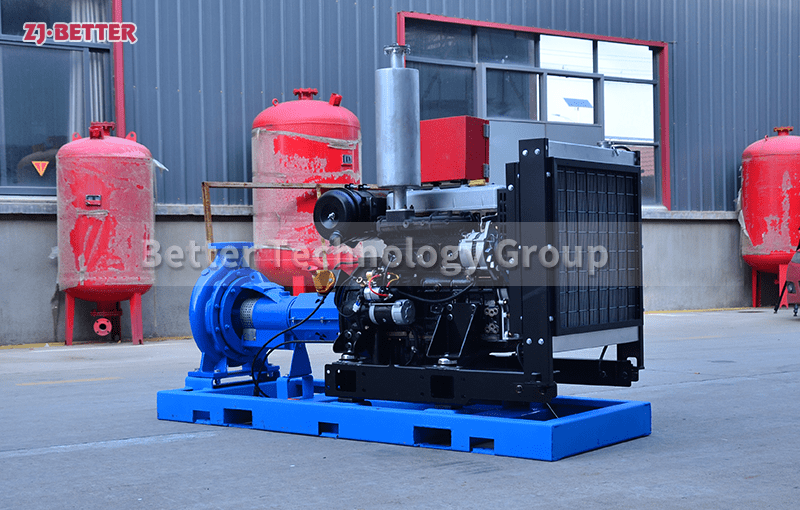

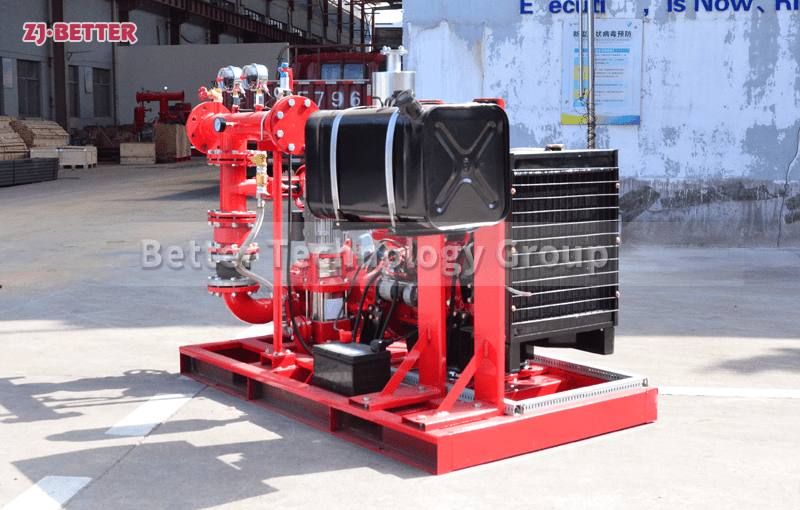

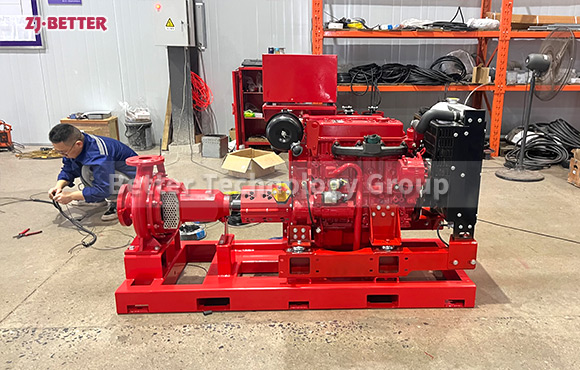

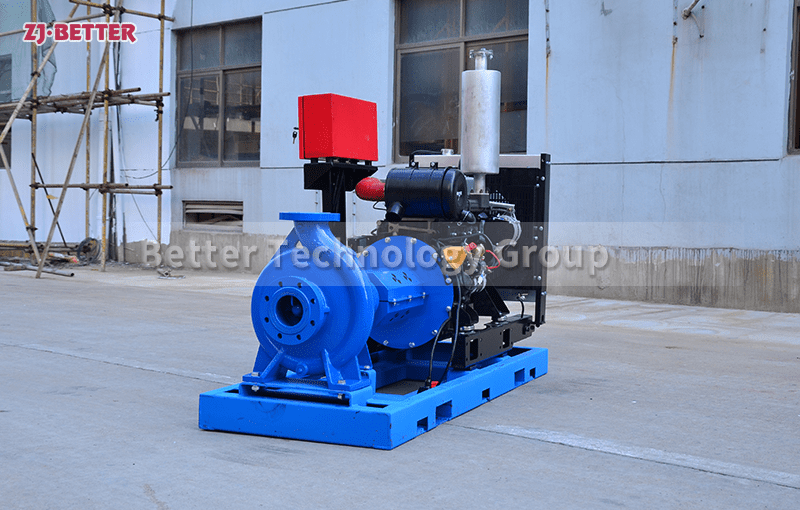

Diesel engine fire pump sets are mainly suitable for fire water supply and foam fire extinguishing systems in petrochemical, natural gas, power generation, cotton and linen textiles, warehouses, airports, docks, high-rise buildings and other industries. It can also be used in occasions such as water ships, offshore oil tankers and fire fighting ships. The unit adopts imported diesel engine and fire pump. It has the characteristics of quick start, reliable water diversion, reasonable power reserve, stable operation, high degree of “three modernizations”, wide range of pressure and flow, etc. It is an advanced and reliable fire-fighting equipment.

Rational use and careful maintenance of the pump set is an important prerequisite to ensure the normal and reliable operation of the pump set, give full play to the emergency function and prolong the service life. In order to make the pump set operators familiar with its structural features, master the use and maintenance methods, and make good use of the pump set, we have compiled this manual for the reference of the set operators.

Diesel engine fire pump installation instructions:

1. The fire pump room where the unit is installed should be as close to the water pool as possible, the water inlet pipe of the water part should be as short as possible, and the elbows should be as few as possible to reduce the resistance of water inlet. And should ensure that the space of the unit is spacious enough to facilitate the operation and maintenance of the unit. The pump room is equipped with hoisting equipment, and insulation measures should be taken to ensure that the temperature of the pump room is ≥ 5°C;

2. The foundation of the unit should be solid and solid, reinforced concrete, and the size should be based on the bottom frame of the pump unit to extend 100-200mm to the periphery, and set up sewage drains and cable trenches;

3. When the unit is placed on the foundation, it should be adjusted by wedges or pads, and the levelness should be checked with a spirit level. After tightening the foundation bolts, check the levelness again, and then grout when it is suitable. No gaps or air pockets should be left during grouting;

4. The water pipes at the inlet and outlet of the unit should be independently supported and installed firmly. Do not use the fire pump as a pipe support. And take measures to prevent the fire pump inlet and outlet load from being too large, and the phenomenon of no air bag in the inlet pipe;

5. The muffler should be installed outdoors, and the diameter of the exhaust pipe should not be smaller than the size required by the unit, but the exhaust pipe should be as short as possible, with as few elbows as possible in order to prevent the diesel engine from having a large exhaust resistance and affecting the power of the diesel engine. output. The exhaust pipe should be supported independently, never with the engine support. In order to prevent the high temperature of the exhaust pipe from hurting people, heat insulation protection measures should be taken at a height close to people’s touch.

.jpg)