Portable hand-held diesel fire pump with high output power

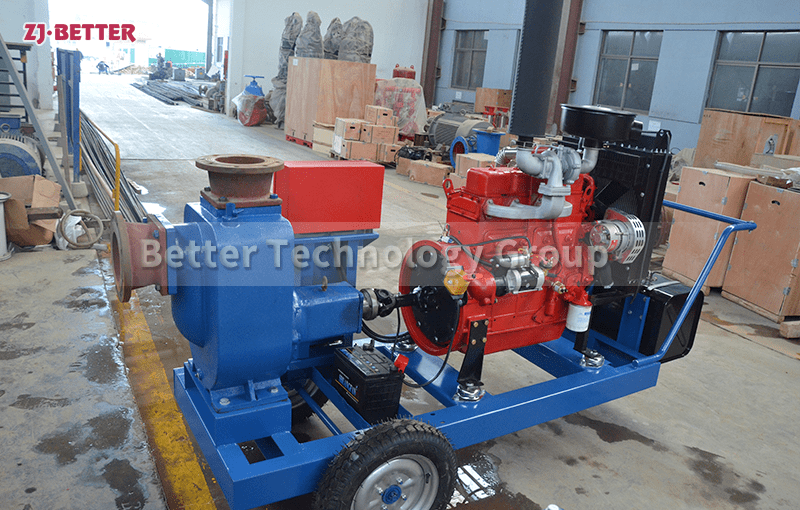

The fire safety hand-held mobile fire pump has the characteristics of high power, light weight, simple structure, convenient use and maintenance, and quick start. The water supply equipment is part of the work of the hand pump, and the hand lift frame is the support of the whole equipment. When in use, drag the joystick to the horizontal direction to extend the pump. Because the hand-held fire pump is light and handy, it will not be restricted by traffic, power engineering, and regions. It has been widely used to extinguish fires in industrial and mining enterprises, warehouses, seaports, ports, and villages. or incipient fire incidents in areas not immediately accessible.The fire safety hand-held mobile fire pump has the characteristics of high power, light weight, simple structure, convenient use and maintenance, and quick start. The water supply equipment is part of the work of the hand pump, and the hand lift frame is the support of the whole equipment. When in use, drag the joystick to the horizontal direction to extend the pump. Because the hand-held fire pump is light and handy, it will not be restricted by traffic, power engineering, and regions. It has been widely used to extinguish fires in industrial and mining enterprises, warehouses, seaports, ports, and villages. or incipient fire incidents in areas not immediately accessible.

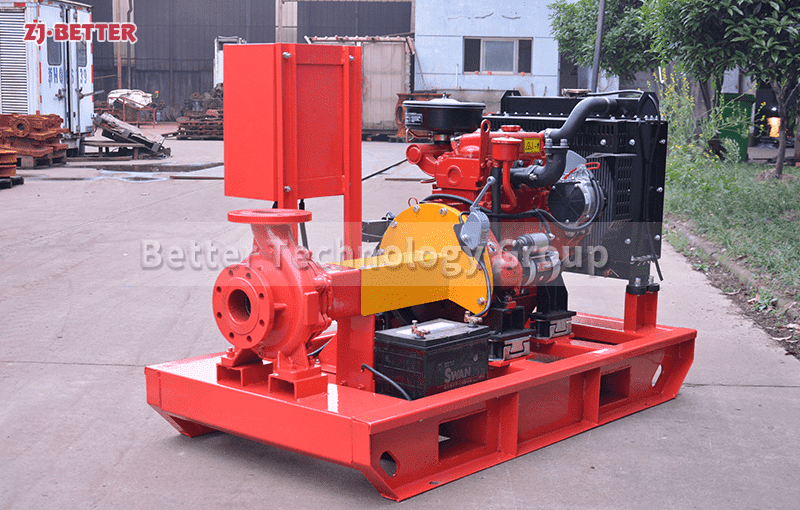

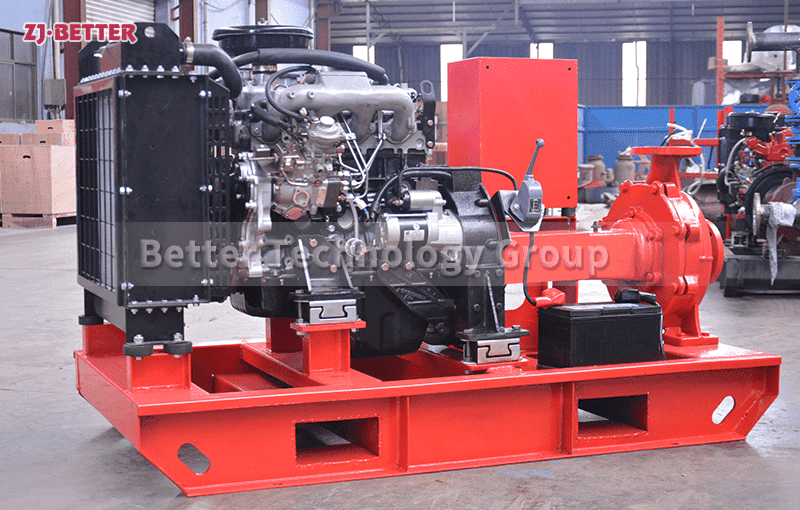

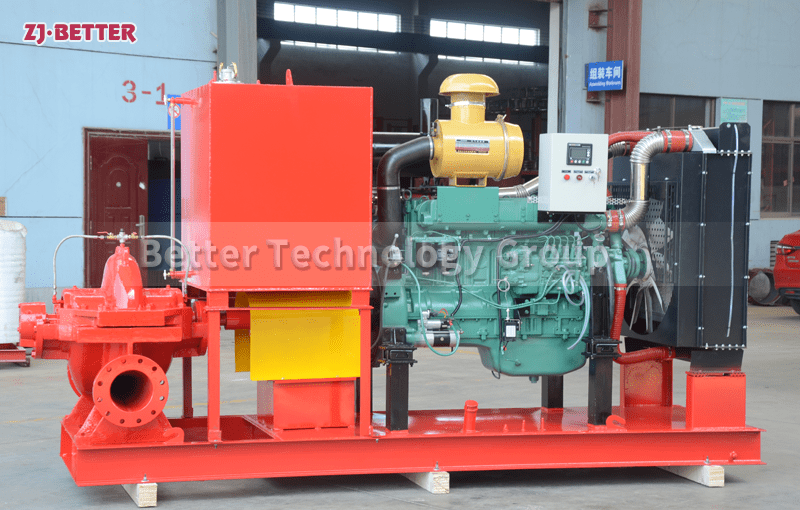

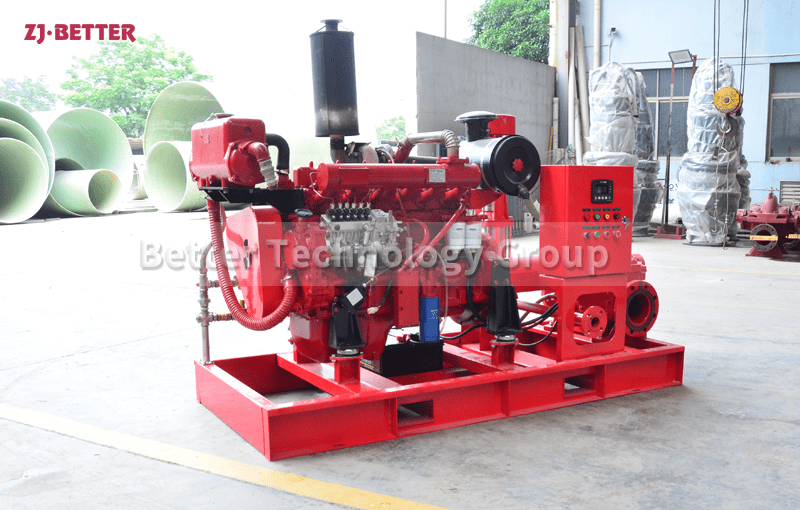

Hand-held diesel engine fire pump is a fire pump unit with resource and light diesel engine components. The hand-held diesel engine fire pump unit is composed of diesel engine and fire pump system software supporting facilities. The space layout should be effective, the structure should be compact, the volume should be small, and the net weight should be ≦100kg. The whole equipment is composed of centrifugal water pump, water dispenser, diesel engine and other components .

The main application is the hand-held diesel engine fire pump, which is mainly used for fire safety in fire brigades, various professional fire brigades, industrial and mining enterprises, counties, towns, etc. In places where fire vehicles cannot operate, hand-held fire pumps It can be used for waterlogging, drought, greening and garden irrigation, power supply and emergency disaster relief rationalization equipment.