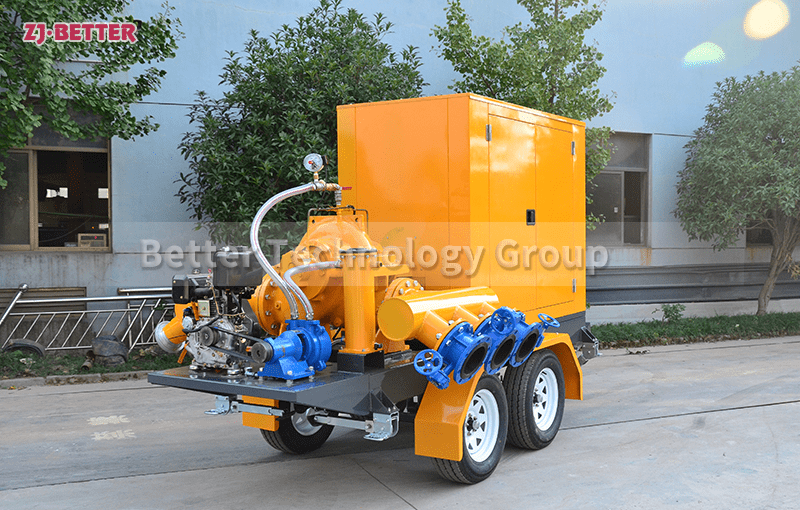

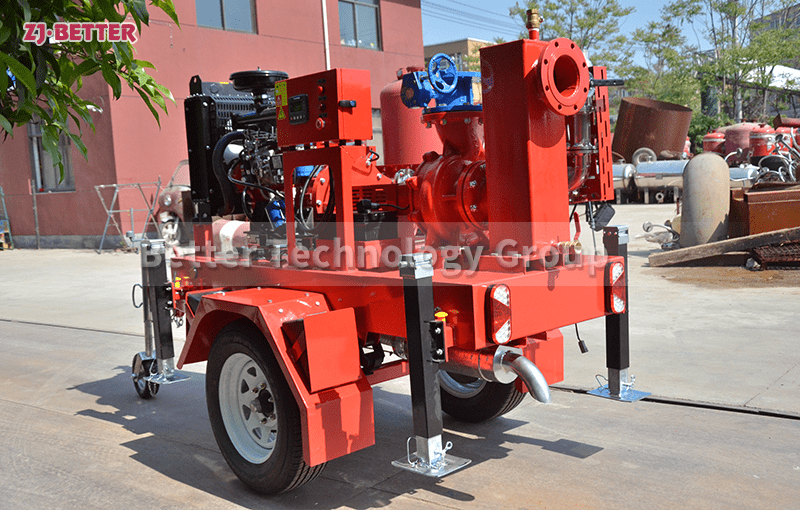

Performance and Applications of Dual-Axle Trailer Mounted High-Flow Diesel Fire Pump

High-performance mobile fire pumps with powerful pumping capacity and fast response performance are suitable for a variety of firefighting and emergency rescue scenarios. Their rugged structure and easy operation ensure a stable water supply and efficient firefighting at critical moments.

The dual-shaft wheeled high-flow mobile diesel fire pump is a high-performance equipment designed specifically for large-scale firefighting, long-distance water supply, and emergency rescue. It perfectly integrates the diesel engine power system, centrifugal pump body, trailer chassis, and control system to form an efficient, flexible, and reliable overall water supply solution. This pump station was designed with complex operating environments and changing rescue needs in mind, and therefore has outstanding advantages in power performance, flow output, endurance, structural stability, and ease of operation. Its core power unit uses a high-power, low-fuel-consumption, high-torque industrial-grade diesel engine with excellent starting performance and durability. It can start quickly and operate continuously even in harsh conditions such as low temperature, high temperature, humidity, and dust. The diesel engine directly drives the centrifugal pump through a high-strength elastic coupling, effectively reducing energy loss and improving transmission efficiency. The pump body is made of high-quality alloy materials with high wear resistance and corrosion resistance, and has undergone precision processing and dynamic balancing tests to ensure stability and low vibration under long-term high-load operation. The impeller design has been hydraulically optimized to achieve high flow output at low speeds, with a maximum flow rate of several Thousands of cubic meters per hour, meeting the fire water supply needs of high-rise buildings, large warehouses, docks and ports, petrochemical enterprises, airports and other places. It is also suitable for flood control, large-scale water supply, agricultural irrigation and other scenarios. The trailer chassis is a double-axle design, equipped with high-load-bearing solid tires and suspension systems to ensure the stability and safety of the equipment when driving on highways or unpaved roads. The load distribution of the double-axle structure is more balanced, and it can carry larger pump groups and fuel tank capacities, thereby extending continuous operation time and reducing refueling frequency. The whole set of equipment has strong mobility and can be transported by pickup trucks, trucks and other vehicles. It can be towed by a vehicle and quickly deployed to the mission site, saving valuable rescue time. The control system adopts an intelligent design and is equipped with a digital display screen, which can monitor key data such as diesel engine speed, oil pressure, water temperature, running time, and pump pressure and flow in real time. Some models also support remote monitoring and automatic start-stop functions, automatically starting the pump group when a fire alarm is triggered or the pipeline pressure drops, thereby improving emergency response speed. The whole machine has a high protection level, the electrical part has a waterproof and dustproof design, and the exterior is equipped with a sturdy metal protective cover and soundproof box, which effectively reduces noise emissions and protects the internal components of the equipment from environmental influences. The fuel system utilizes a large-capacity fuel tank and a high-efficiency fuel filtration system to ensure a continuous and stable fuel supply to the diesel engine, making fuel impurity clogging less likely during long-term operation. The cooling system is optimized for high-intensity operating conditions and is equipped with a large-size radiator and a high-efficiency cooling fan to effectively prevent the engine from overheating during long-term full-load operation. The lubrication system uses a high-efficiency oil pump and a full-flow filter to ensure that all internal engine components are always well lubricated, thereby extending the service life. In addition, this equipment also has significant advantages in terms of maintenance convenience. The body layout is reasonable, and the access ports of key components, filter element location, and lubricating oil filling port are convenient for daily inspection and maintenance, reducing downtime and maintenance costs. The overall structure of the dual-axis wheeled high-flow mobile diesel engine fire pump is sturdy and reliable. The chassis welding is made of high-strength steel and has undergone anti-corrosion treatment. It is not easy to rust in harsh environments such as humidity and salt spray for long-term use. High-pressure flanges and sealing gaskets are used for the pump body and pipeline connections to ensure no leakage during high-pressure water delivery. The sealing system adopts a combination of mechanical seals and packing seals to effectively extend the service life and reduce maintenance frequency. In performance tests, this type of pump unit has demonstrated excellent The unique head and flow matching capability allows for stable pressure output, even over long distances. This is crucial for operations requiring simultaneous water supply to multiple fire hydrants or monitor lines. The diesel engine’s fuel efficiency and endurance ensure continuous operation in remote, off-grid areas, providing a solid foundation for emergency rescue efforts. The versatility of this pump unit not only makes it highly effective in firefighting, but is also widely used in industries such as mine drainage, municipal engineering, industrial water supply, and temporary pipeline construction. Its rapid deployment and efficient operation enable users to complete large-scale water supply tasks in record time. Overall, the dual-axle, wheeled, high-flow mobile diesel fire pump, with its powerful power output, exceptional high-flow capacity, flexible maneuverability, excellent structural stability, and user-friendly intelligent control system, has become the preferred equipment for responding to large-scale fires, floods, and other emergency water supply operations. Its design fully considers the diverse and demanding nature of practical scenarios, ensuring reliability while maximizing efficiency and safety. It is an indispensable component of modern firefighting and emergency rescue systems.