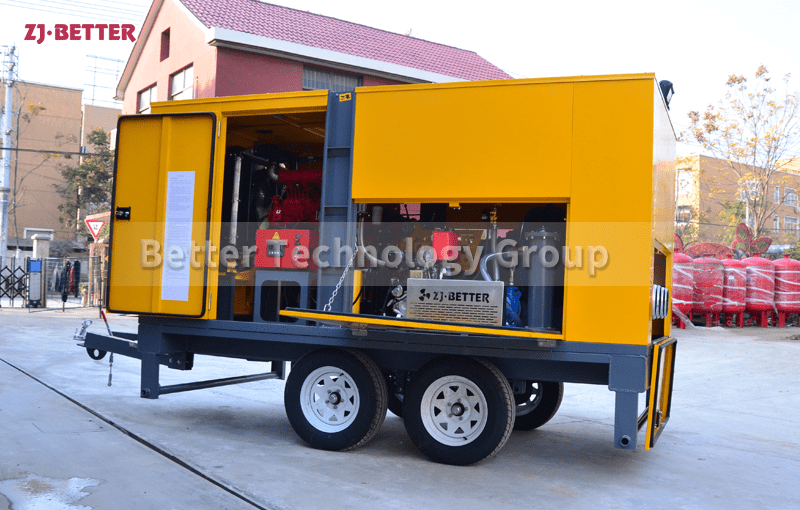

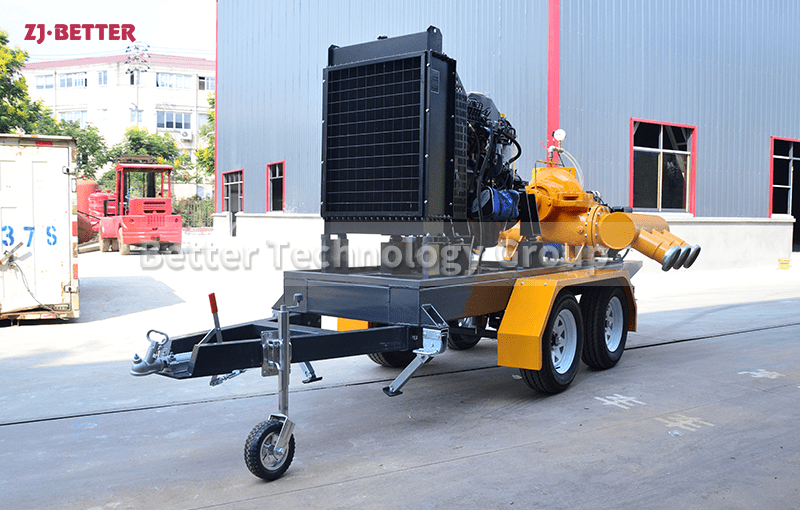

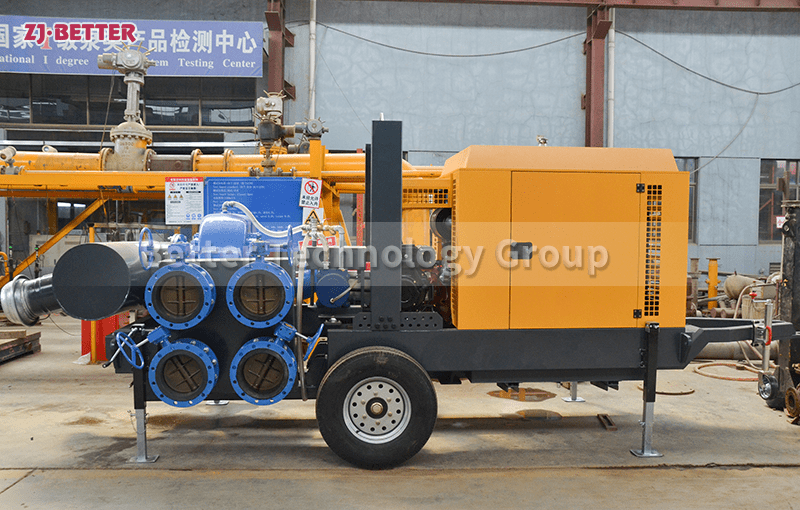

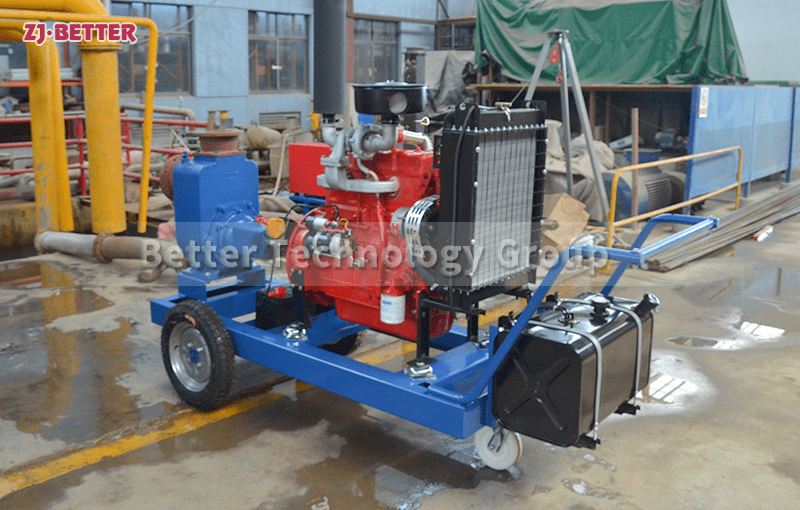

Powerful function of mobile pump truck

The mobile pump truck was developed based on the characteristics of suddenness, urgency, operational diversity, and social influence formed by factors such as long-term storage of emergency rescue and disaster relief equipment, lack of maintenance, harsh operating environment, and special operating requirements. Compared with traditional pumps The new generation of mobile pump trucks integrates a number of modern concepts and has more powerful functions.

Another name for mobile pump truck: flood control and drainage mobile pump truck, mobile diesel engine self-priming, mobile diesel engine water pump, trailer-type emergency drainage pump truck, four-wheel mobile pump truck, diesel engine and self-priming pump combination, manual and automatic control can be set. Diesel engine self-priming pump integrates self-priming and non-clogging sewage discharge. It adopts axial backflow external mixing type, and through the design of pump body and impeller flow channel, it does not need to install bottom valve and tank water diversion like ordinary self-priming clean water pumps. It can absorb and discharge liquids containing large solid particles and long fiber impurities, and can be used for municipal sewage discharge, flood control, drought relief, river pond breeding, light industry, papermaking, textile, food, chemical industry, electrical industry, fiber, slurry and mixed suspension and other media conveying diesel engines Self-priming pump.