Round-the-Clock Reliability: Application Advantages of Electric Fire Pumps in High-Density Buildings

The preferred solution for high-density building fire protection systems! Learn how electric fire pumps can achieve stable operation around the clock, low maintenance, intelligent control, energy saving and environmental protection, and provide reliable fire protection for modern cities.

In the context of rapid development of modern cities, high-density building complexes have become the core part of urban landscape. Such buildings are concentrated, complex in structure, and densely populated, which puts higher requirements on fire safety. Under this trend, electric fire pumps, as a key component of building fire protection systems, have gradually become the preferred configuration for high-rise buildings, large commercial complexes, industrial parks and other places with their high efficiency, reliability and intelligent performance. This article will focus on the application advantages of electric fire pumps in high-density buildings, and systematically explain their technical characteristics, operational reliability, energy-saving effects, control methods and their far-reaching impact on modern fire protection systems.

Electric fire pumps use motors as power sources and use stable power systems to drive water pumps to ensure that they provide strong and continuous water pressure support for sprinkler systems, fire hydrants, etc. in the first time of a fire. Compared with traditional diesel fire pumps, electric fire pumps have significant advantages such as quick start-up, easy maintenance, low operating noise, and no exhaust emissions. These characteristics not only conform to the development direction of energy conservation and environmental protection of green buildings, but also reduce long-term operation and maintenance costs and improve the response efficiency of fire protection systems.

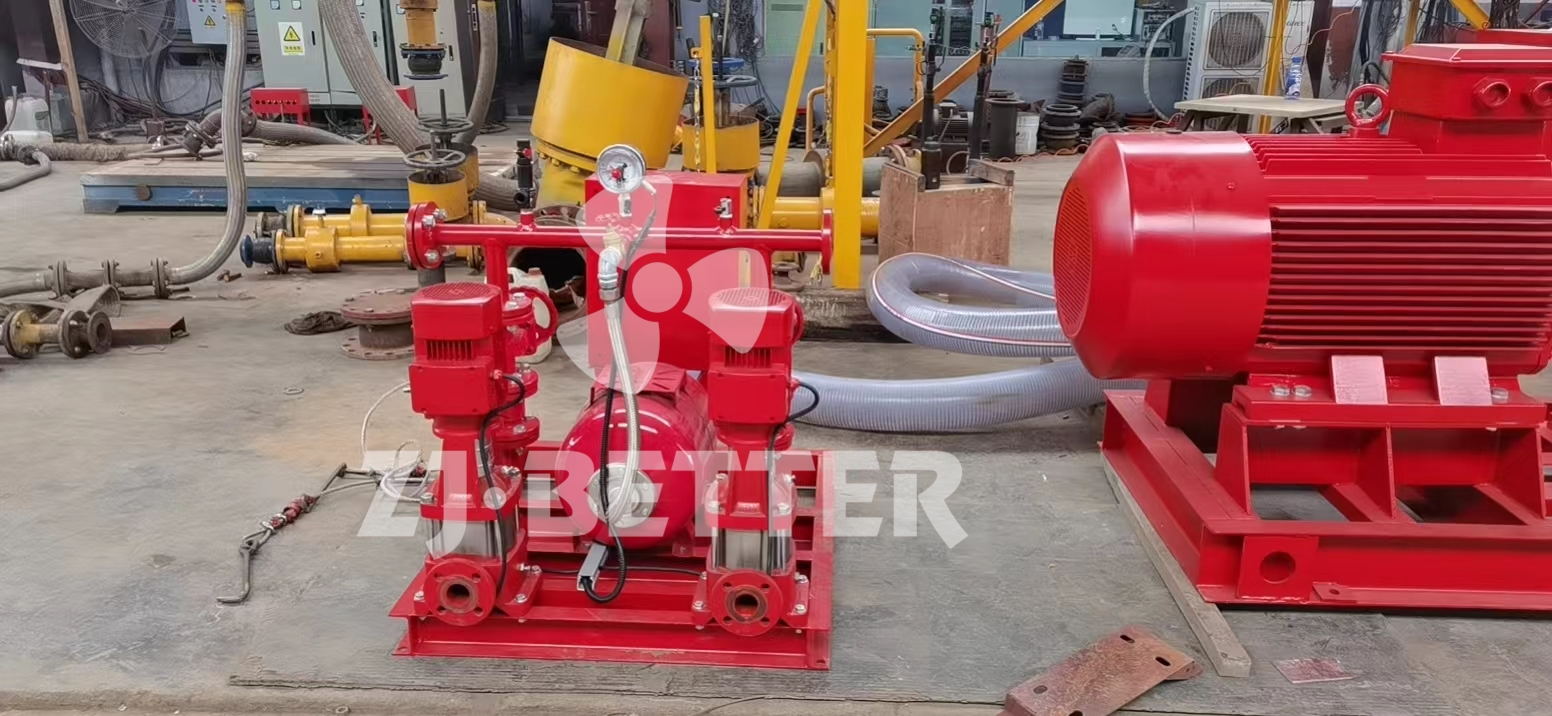

In high-density buildings, due to the compact space, the equipment layout requires precision and compactness. Electric fire pumps have great space advantages due to their compact structure and small footprint. The pre-installed modular design makes on-site installation more convenient, shortens the construction period, and improves the overall integration of the fire protection system. The integrated design of the control cabinet and the pump group enables operators to quickly complete tasks such as equipment start and stop, status monitoring, and fault judgment, greatly improving the efficiency of emergency management.

In terms of operational reliability, electric fire pumps fully demonstrate the advantages of all-weather uninterrupted work. It uses a high-efficiency three-phase asynchronous motor as the driving core, and has multiple safety protection mechanisms such as overload protection, short circuit protection, and phase loss protection to effectively avoid accidental damage. At the same time, the pump body is made of high-strength cast iron or stainless steel, which has excellent corrosion resistance and high temperature resistance. It can operate stably even in harsh climates or high-load environments, ensuring the long-term water supply capacity of the fire protection system.

The intelligence of the control system is a highlight of modern electric fire pumps. Through PLC programming control, remote monitoring module and networking with the fire center, real-time monitoring, automatic start and stop, status alarm and fault recording of the pump group can be realized. The system supports multiple communication protocols such as Modbus and RS485, which facilitates access to the smart fire protection platform, enhances information sharing and linkage capabilities, and promotes the intelligent upgrade of the fire protection system. This digital operation and maintenance mode reduces manpower investment, improves response speed, and provides accurate data support for system optimization and maintenance.

In addition, the electric fire pump is almost noiseless during operation, which not only improves the comfort of the building, but also is more in line with hospitals, office buildings, residential areas and other places with strict requirements on environmental noise. This low-noise operation characteristic further expands the scope of application of the product and also reflects the optimized design of the product in details.

In terms of maintenance, compared with diesel pumps, electric fire pumps save tedious processes such as oil replacement, fuel replenishment, and air intake and exhaust system cleaning. Regular inspections only need to focus on electrical connections, insulation performance, pump shaft lubrication and other key points, which greatly reduces the maintenance workload and reduces the risk of human errors. At the same time, some high-end products also support remote operation and maintenance and regular self-inspection to further improve equipment availability.

From an energy perspective, electric fire pumps have low operating costs and high energy utilization. Especially after adopting high-efficiency motors and frequency conversion control technology, it can dynamically adjust the output power according to the actual flow rate in daily linkage testing or standby water supply mode to achieve energy-saving operation. In contrast, diesel pumps are gradually restricted in use due to their low efficiency and carbon emissions caused by long-term low-load operation.

In summary, electric fire pumps have become irreplaceable firefighting equipment in high-density buildings with their stable, intelligent and environmentally friendly characteristics. It not only improves the overall fire protection level of buildings, but also promotes the development of urban safety management towards intelligence and greening. At a time when the trend of high-rise and intelligent cities is becoming increasingly obvious, electric fire pumps will continue to play a key role in more core construction projects with their superior performance, and become a strong guarantee for protecting life and property safety.