Speed Meets Efficiency: Key Benefits of Smart-Controlled Electric Fire Pumps

The intelligent electronically controlled electric fire pump combines the advantages of energy saving and rapid response. It is suitable for a variety of scenarios such as high-rise buildings and commercial complexes. It has integrated design and intelligent control to ensure fire safety and easy maintenance.

In modern buildings and industrial facilities, the reliability of fire protection systems has become one of the key factors in measuring the level of safety assurance. With the advancement of technology and the improvement of safety standards, traditional fire pumps have been unable to meet the stringent requirements of new buildings and industrial scenarios for “fast, accurate, stable and economical” in terms of operating efficiency, response speed and intelligent management. Based on this background, intelligent electronically controlled electric fire pumps have emerged as the times require and have become the preferred solution for upgrading the current fire pump system. Through efficient motor drive, intelligent control system configuration and modular integrated design, this equipment not only significantly improves energy utilization and operational convenience, but also ensures the timeliness and continuity of fire response at critical moments.

Compared with traditional diesel-driven fire pumps, electric fire pumps have shown obvious advantages in energy supply stability, startup response speed and operation and maintenance cost control. Especially in scenarios with a complete urban power supply system, the electric pump group realizes automatic adjustment of pump speed and pressure through an intelligent variable frequency control system, which greatly reduces power consumption while ensuring fire extinguishing efficiency. In addition, its fully enclosed silent design not only reduces operating noise, but also optimizes the indoor and outdoor installation environment. It is widely used in places with high sensitivity to fire protection systems, such as high-rise buildings, commercial complexes, medical institutions, and data centers.

The introduction of the intelligent electric control system is one of the core highlights of this product. The equipment forms a complete intelligent operation system through a variety of intelligent components such as human-machine interactive control panel, PLC programmable logic controller, and remote communication interface. The system has multiple functions such as real-time monitoring, fault alarm, automatic recording, and parameter setting. Managers can grasp the operating status of the pump group at any time through the background remote monitoring platform or local interface, which is convenient for daily maintenance and rapid troubleshooting, and significantly improves the visualization and intelligence level of system operation.

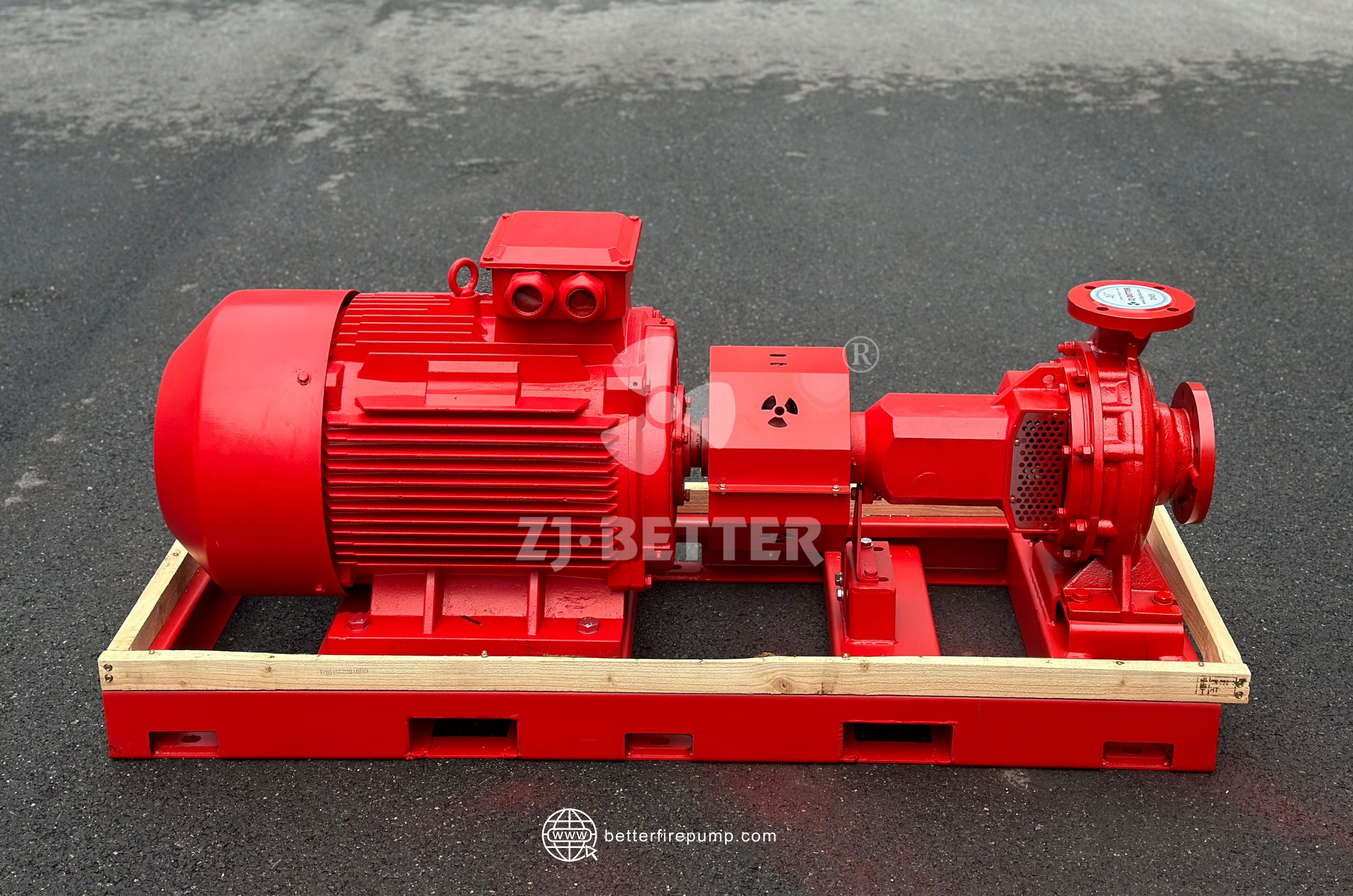

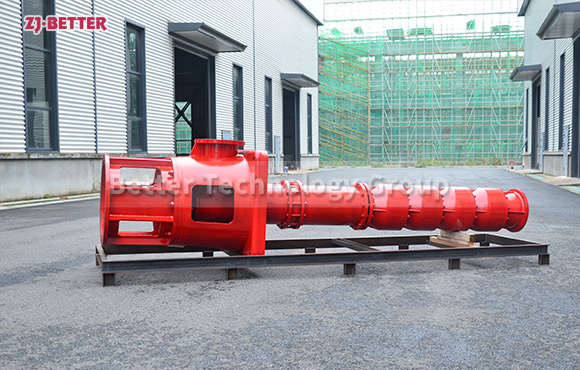

From a structural point of view, the electric fire pump group adopts a standardized and modular combination method to highly integrate the motor, water pump, control cabinet, pressure vessel and pipeline system on the same base, which greatly saves installation space and time costs. This design enables the equipment to be directly hoisted in place as a whole, eliminating the cumbersome on-site pipeline connection operations, improving construction efficiency, and reducing installation errors and later maintenance difficulties. The base adopts heavy-duty carbon steel spraying technology, which effectively improves the corrosion resistance and equipment stability, and adapts to various complex environments.

In terms of power configuration, the electric fire pump is equipped with an efficient and energy-saving motor with the characteristics of small starting current, strong overload capacity, low temperature rise, and long service life. The water pump part is made of corrosion-resistant alloy material, the impeller is tightly combined with the pump body, and the flow channel design is optimized to effectively reduce the liquid flow resistance, ensuring stable water supply under full load or variable load conditions. To further improve performance, the pump group can also be equipped with additional functional modules such as dual power switching device, voltage stabilization module, lightning protection device, etc., to fully adapt to different power conditions and external environment requirements.

Considering the needs of different usage scenarios, this series of intelligent electronically controlled electric fire pumps supports a variety of starting methods, such as soft start, star-delta start, auto-coupling step-down start, etc., and reserves linkage interfaces with fire automatic sprinkler system and fire control center to facilitate the formation of system cascade control. At the same time, it has functions such as automatic switching of water replenishment in the municipal pipeline network, automatic start and stop of the standby pump, and real-time feedback adjustment of water pressure, which strengthens the system’s rapid response and automatic compensation capabilities for sudden situations, and truly achieves “people are far away, and the pump is escorting”.

In terms of maintenance, the product adopts integrated wiring and built-in wiring channel design, which reduces the exposure of external lines and reduces the probability of electrical failures caused by cable aging. The control cabinet door is equipped with waterproof sealing strips and dust covers, which increase the protection level to IP55 or above, and is suitable for a variety of indoor and outdoor installation environments. The control system has a self-diagnosis function. When abnormal conditions such as motor overload, abnormal vibration of the pump body, and excessive water pressure occur, it can immediately issue an audible and visual alarm and record the fault code to assist technicians in quickly locating and restoring equipment operation.

In order to meet the needs of different customers, the electric fire pump group can be flexibly customized according to technical parameters such as flow, head, voltage level, and access system, and supports full-line benchmarking of standards such as “Specifications for Installation and Acceptance of Fixed Fire Facilities” and “Architectural Design Fire Protection Specifications” in fire acceptance. All equipment in the factory has passed multiple testing processes such as static pressure test, water pump performance curve test, electrical linkage test, etc. before leaving the factory to ensure that each pump set can be seamlessly connected to the system after arriving at the site and put into use quickly.

In summary, this intelligent electronically controlled electric fire pump set not only has excellent energy-saving performance and response efficiency, but also shows all-round product advantages in terms of structural layout, control system, human-computer interaction, installation convenience and adaptability to multiple environments. Its birth is in line with the development trend of intelligent, intensive and green modern building fire protection systems, and is the preferred equipment solution for many project parties in the process of creating high-quality fire protection systems.