Big Power in a Small Package – The Advantage of Mini Diesel Fire Pumps in Fire Protection Systems

In modern architecture and industrial environments, efficient space utilization is a key consideration. Mini diesel fire pumps, with their compact size, flexible installation, and powerful performance, are the ideal solution for fire protection in confined spaces.

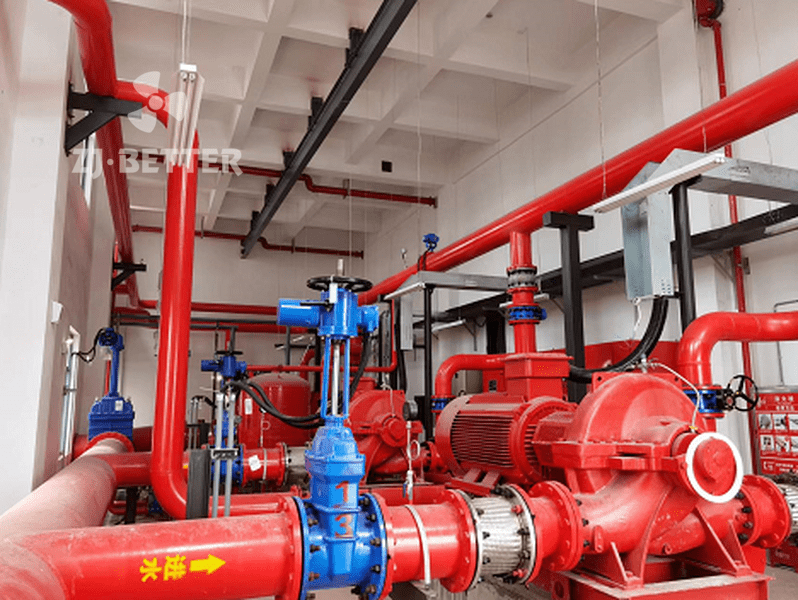

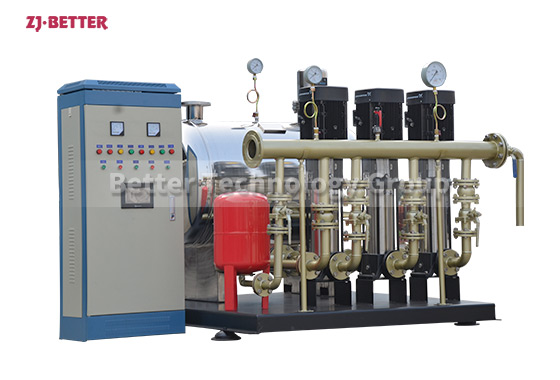

This integrated unit combines a diesel engine, high-efficiency pump, and intelligent control system, ensuring rapid startup and stable water supply during power outages or in areas without electricity. Its space-saving design makes it perfect for use in basements, equipment rooms, and mobile fire trucks—especially suitable for high-rise buildings, warehouses, chemical plants, and any location where emergency response time is critical.

With low maintenance requirements, excellent fuel efficiency, and long service life, the mini diesel fire pump is a cost-effective yet high-performance choice for modern fire protection needs.

Specializing in the research, development, and manufacturing of fire pump systems, this enterprise is committed to delivering efficient and reliable fire protection solutions to clients worldwide. Its product range includes diesel engine fire pump sets, electric pump units, pressure stabilization systems, and integrated pump stations, which are widely used in municipal projects, high-rise buildings, industrial parks, and petrochemical facilities.

With advanced production technologies and a strict quality control system, the company consistently develops customized products tailored to diverse operational environments. It has gained extensive expertise in compact and emergency pump unit design, offering space-saving and easy-to-maintain equipment with excellent performance.

Driven by the core values of “Safety, Efficiency, and Innovation,” the company’s products have been exported globally and are well-received by clients for their reliability and quality.