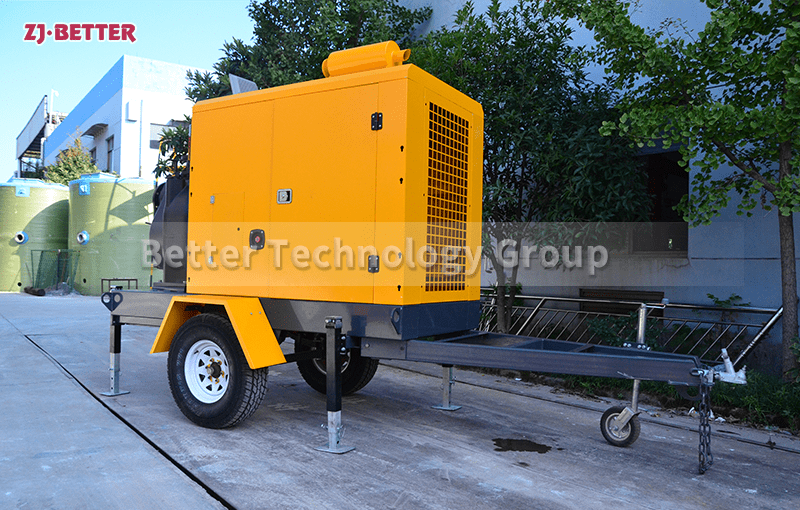

Firefighting Emergency Mobile Pump Truck: Ensuring Safety

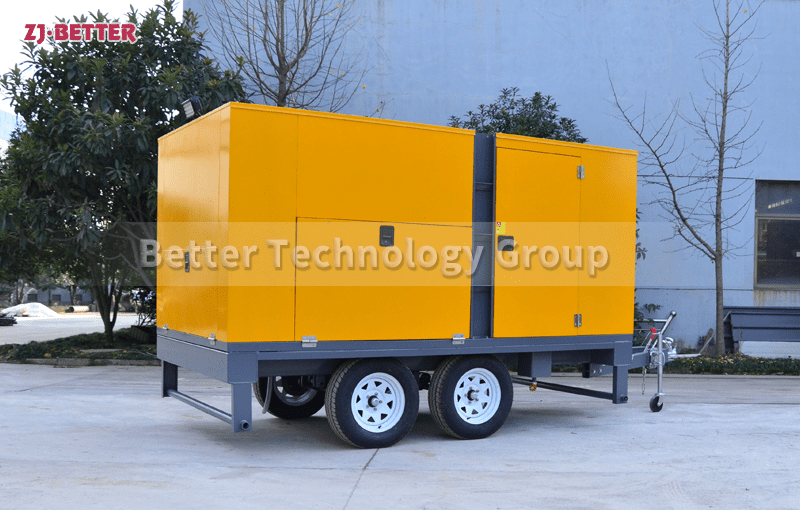

A mobile pump truck is a specialized firefighting vehicle designed for emergency response. Equipped with a water pump, water tank, hoses, and other firefighting equipment, it serves to quickly supply water and pressure to control fires and emergencies. Its functions encompass temporary water sourcing, supplemental water supply for areas lacking resources, and boosting water pressure for varied fire scenarios. The truck’s components include a chassis, water pump, tank, hoses, nozzles, control panel, and additional firefighting tools. The operational process involves arriving at the scene, setting up water sources, activating the pump, conducting firefighting operations, and monitoring parameters. Overall, the mobile pump truck’s pivotal role lies in providing essential resources for firefighting efforts, ensuring efficient fire control and property protection.

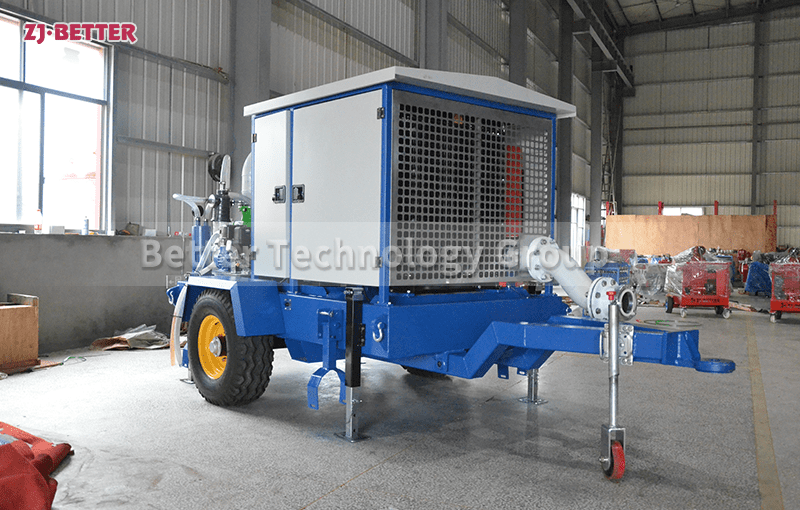

A mobile pump truck is a specialized vehicle used for water supply and firefighting in emergency situations. It typically carries a water pump, water tank, firefighting hoses, and other necessary firefighting equipment, enabling rapid response to fires, accidents, and other urgent incidents by providing sufficient water supply and pressure for firefighting operations. Here is a basic introduction to a mobile pump truck:

- Functions and Uses:

A mobile pump truck is primarily used for the following purposes:

– Temporary water supply: At the scene of a fire, the mobile pump truck can draw water from nearby sources such as water towers, rivers, or wells, and then use the water pump to deliver water to firefighting personnel for extinguishing fires.

– Supplementing firefighting water sources: In areas with limited firefighting water sources, the mobile pump truck can provide supplementary water sources for other firefighting vehicles, ensuring firefighting operations can continue.

– Increasing water pressure: The water pump on the mobile pump truck can provide higher water pressure, helping to deliver water to higher or farther locations to address different types of fires.

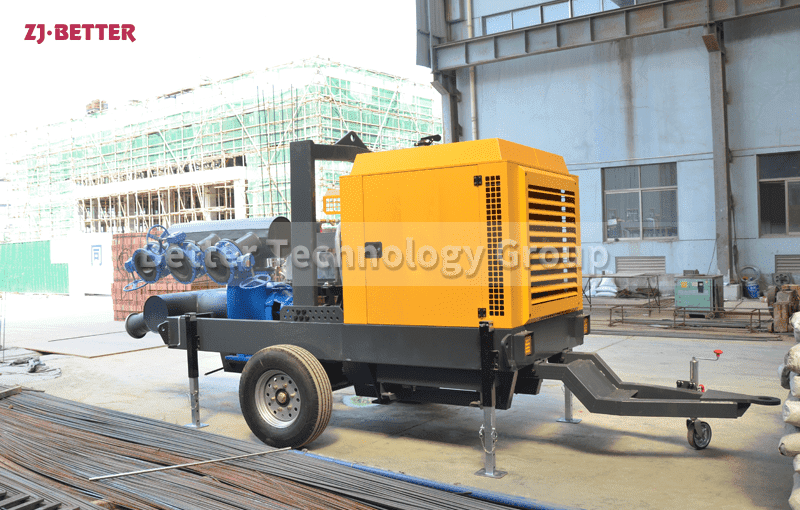

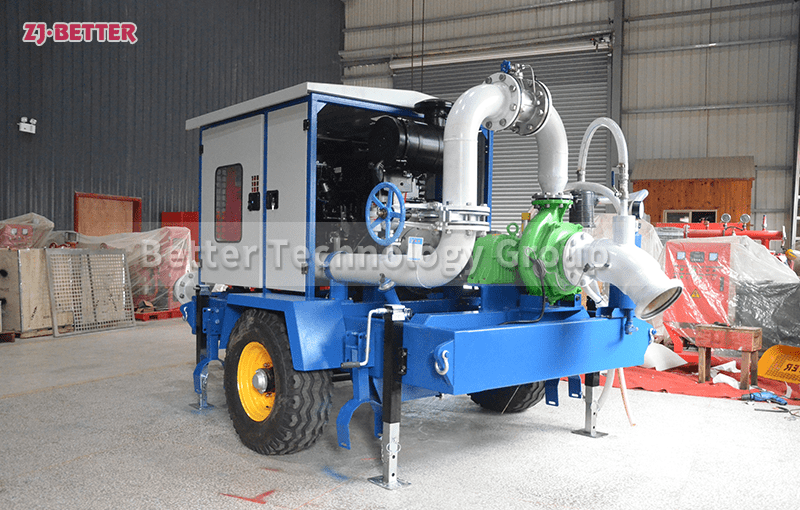

- Components:

A mobile pump truck typically includes the following main components:

– Chassis: The vehicle’s foundation, often chosen based on the type of truck, such as a truck or a utility vehicle.

– Water pump: Used for pumping water and increasing water pressure to effectively deliver water to the fire source.

– Water tank: A container for storing firefighting water, with varying capacities depending on the vehicle model and needs.

– Fire hoses: Connecting the water pump to the nozzles, these hoses transport water to the desired location.

– Nozzles: Usually located at the front, sides, or top of the vehicle, these are used to spray water onto the fire source.

– Control panel: Interface for operating the water pump, adjusting water pressure, and other parameters.

– Other firefighting equipment: Such as fire extinguishers, fire axes, firefighting tools, etc.

In conclusion, mobile pump trucks play a crucial role in firefighting emergencies, providing essential water supply and pressure to firefighters to swiftly and effectively control fires, safeguarding lives and property. While variations may exist in different regions and countries, the fundamental functionality and purpose of mobile pump trucks remain largely consistent.