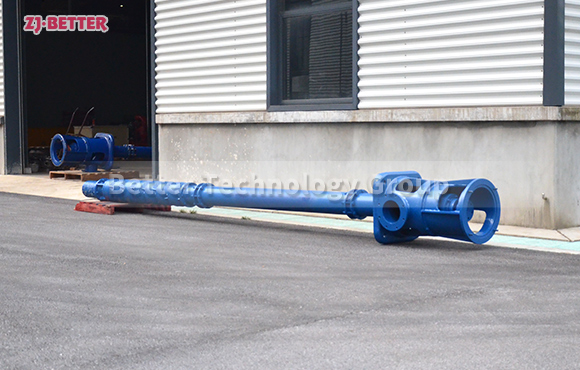

Heavy-Duty Fire Pump Electric Motor | Durable Design for Long-Term Operation

High-power fire pump motors are designed to be efficient and durable, supporting long-term continuous operation. They feature high energy efficiency, low noise, high protection levels, and multiple starting methods. They are widely used in fire protection systems in high-rise buildings, industrial parks, petrochemical storage facilities, and infrastructure to ensure stable and reliable water supply.

High-power motors specifically designed for fire pumps are essential core power equipment in modern firefighting systems. Their design goal is to provide continuous, stable, and efficient driving power for fire pumps, ensuring long-term, uninterrupted operation in emergencies such as fires, and providing reliable support for the entire fire water supply system. These motors are manufactured using high-strength silicon steel sheets and high-grade insulation materials, ensuring low losses and low temperature rise even under high-load conditions. This ensures stable output power even during hours or even dozens of hours of continuous operation, without performance degradation due to overheating or insulation aging. Their power ratings range from tens to hundreds of kilowatts, meeting the needs of medium- and large-scale fire pumps. These motors are customizable to meet the needs of firefighting systems of varying sizes, including high-rise buildings, large industrial plants, petrochemical storage facilities, airports and terminals, and tunnels and subways. These motors utilize an optimized magnetic circuit structure in their electromagnetic design. Finite element analysis is used to reduce electromagnetic noise and eddy current losses, ensuring high efficiency. These motors typically achieve IE3 or IE4 efficiency ratings, significantly reducing energy consumption and helping users reduce energy costs and carbon emissions while ensuring fire safety. Mechanically, this motor features a thickened casing and high-precision bearings, offering excellent shock and vibration resistance. This ensures smooth operation even under the frequent starts and stops of fire pumps, extending equipment life. The motor’s rotor is dynamically balanced, ensuring vibration levels well below national standard limits during operation. This reduces impact on the pump shaft and coupling, effectively lowering maintenance costs. To adapt to the specific needs of firefighting applications, this motor typically features Class F or H insulation and is equipped with a temperature rise protection device and a thermistor for real-time monitoring of winding temperature. When the temperature exceeds a set point, it automatically issues an alarm or shuts off the power supply, preventing motor burnout and ensuring overall system safety. Furthermore, high-power fire pump motors support a variety of starting methods, including direct start, auto-coupling step-down start, soft start, and variable frequency start. These methods can be flexibly selected based on on-site grid capacity and usage requirements, minimizing starting current surges and improving system stability. The motors typically have an IP55 protection rating or higher, offering excellent dust and water resistance, enabling reliable operation in humid, dusty, and outdoor environments. Some models also offer optional explosion-proof designs for use in flammable and explosive environments. In terms of maintenance, the motor features an external lubrication device and removable end caps, facilitating on-site maintenance and bearing replacement, reducing downtime and improving system availability. Overall, this high-power fire pump motor, with its high power density, high efficiency, strong durability, low failure rate, and easy maintenance, is an ideal choice for ensuring the stable operation of fire water supply systems. It not only meets the fire code’s requirements for continuous water supply capacity, but also provides users with long-term operating cost advantages through energy conservation and consumption reduction. It is a truly high-end drive solution that balances safety, reliability, and cost-effectiveness.