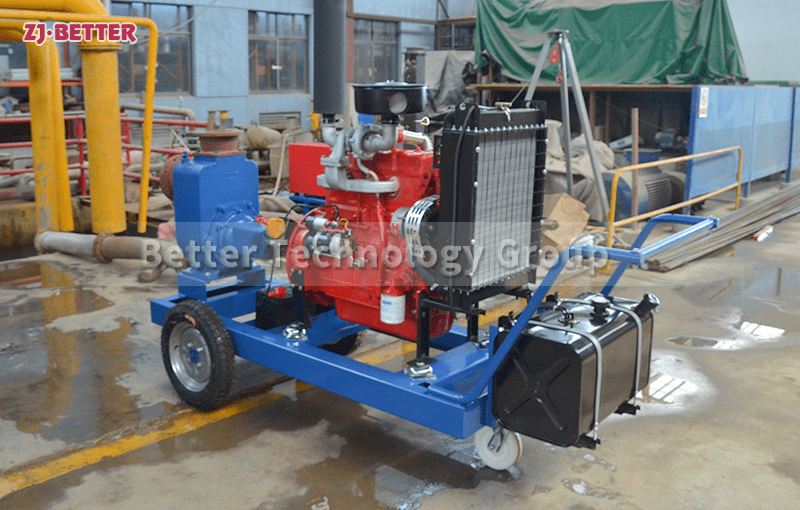

Portable Pumping Power: Mobile Pump Trucks with a split-case centrifugal pump

The combination of a four-wheel mobile pump with a double suction split-case centrifugal pump offers a powerful and efficient pumping solution. This configuration provides numerous advantages, including high efficiency, a wide performance range, smooth operation, low noise, and easy installation and maintenance. It is suitable for transporting clear water or water-like liquids and can be adapted to handle hot water, oils, corrosive liquids, or media with abrasive particles. With applications in firefighting systems, industrial water supply, and hot water circulation, this equipment ensures reliable and efficient pumping performance. By choosing this combination, users can enhance productivity, reliability, and safety in their pumping operations.

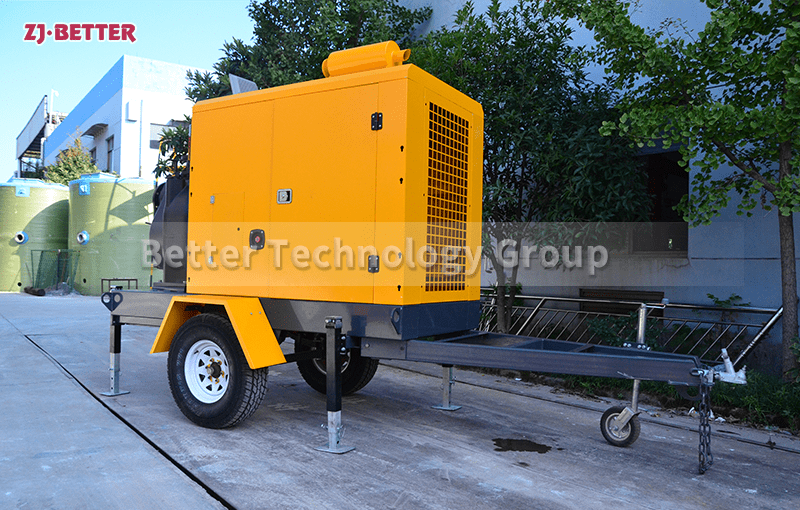

When it comes to flexible and efficient pumping solutions, the combination of a four-wheel mobile pump with a double suction split-case centrifugal pump is the top choice. This powerful pairing offers numerous unique advantages, including high efficiency, a wide performance range, smooth and safe operation, low noise, long lifespan, and easy installation and maintenance. Whether you need to transport clear water or water-like liquids, this equipment configuration is up to the task. Moreover, by changing the impeller material, seal type, or adding a cooling system, it can handle hot water, oils, corrosive liquids, or media with abrasive particles.

The four-wheel mobile pump with a double suction split-case centrifugal pump is not only suitable for firefighting systems but also widely applied in industrial water supply systems, hot water circulation, and various other fields. Its high efficiency ensures fast and reliable pumping, thus enhancing productivity. Additionally, its wide performance range accommodates different flow rates and pressure requirements, allowing for flexibility in various application scenarios.

The equipment’s stable and safe operation, as well as its low noise characteristics, provide a comfortable and quiet working environment. Its long lifespan and easy installation and maintenance guarantee reliability and convenience, reducing downtime and maintenance costs.

Whether you are seeking a new pumping solution or looking to upgrade your existing system, the combination of a four-wheel mobile pump with a double suction split-case centrifugal pump is the ideal choice. By choosing this configuration, you will benefit from efficient, reliable, and safe pumping performance to meet your needs.