Smart Electric Fire Pump Set with Built-in Control Cabinet for Fast Emergency Response

The electric fire pump with integrated control cabinet has compact structure, quick start and intelligent control, and is widely used in fire emergency water supply systems in high-rise buildings, commercial facilities, etc.

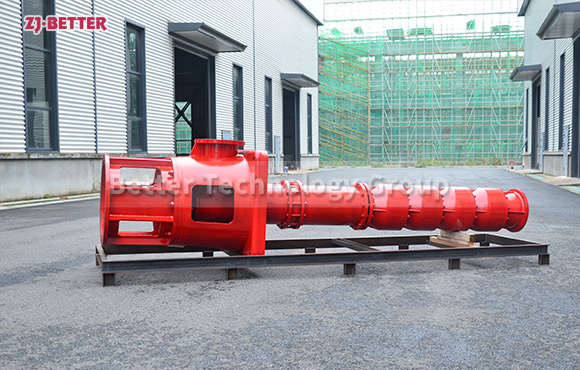

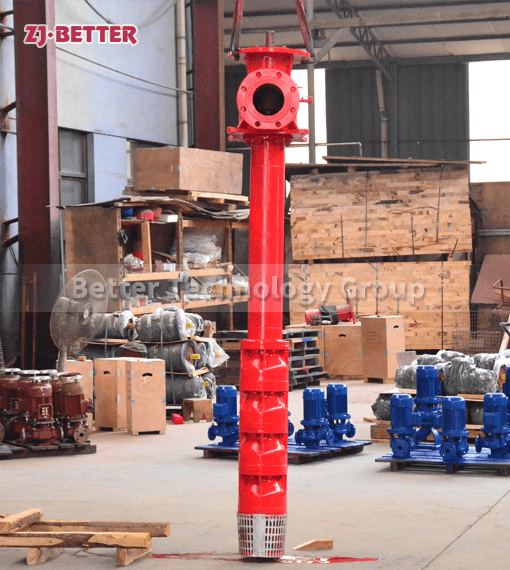

The electric fire pump with integrated control cabinet is an efficient, stable and intelligent fire-fighting equipment, which is widely used in fire-fighting systems of various buildings. With the acceleration of urban construction and the diversification of functions of various buildings, fire-fighting systems face higher technical requirements and reliability standards. Compared with traditional split equipment, the electric fire pump with integrated design not only improves the response speed and operation efficiency of the overall system, but also greatly optimizes the installation space, simplifies the commissioning process, and reduces maintenance costs. The product has a compact structure and an integrated installation. It integrates the motor, water pump, base, automatic control system, electrical control cabinet, instrument monitoring system and necessary valves and pressure gauges. It can start quickly after receiving the fire alarm signal to achieve efficient water supply and fully meet the rapid response needs of high-rise residential buildings, commercial complexes, hospitals, schools, data centers, industrial plants and other buildings in the early stage of fire. From a structural point of view, the equipment connects the water pump and the motor through a coupling and is installed on the same reinforced base. The control cabinet is installed close to one side of the motor, which not only saves floor space, but also avoids the problems of complex wiring and high error rate of the external electric control system. The motor adopts high-efficiency and energy-saving three-phase asynchronous motor or customized variable frequency motor, which effectively reduces energy consumption and noise while ensuring stable power output. It is very suitable for use in modern buildings with high requirements for environmental protection and energy saving. The pump body is made of corrosion-resistant and high-pressure resistant cast iron or stainless steel. After precision processing and dynamic and static balance correction, it has performance characteristics such as large flow, high head and stable water pressure. Especially in the building environment where sprinkler system or fire hydrant system coexists, it can maintain long-term and continuous high-pressure water supply without fluctuation, ensuring the normal operation of fire extinguishing equipment.

As the “brain” of the whole system, the control cabinet integrates multiple intelligent functions such as automatic start and stop, fault detection, signal output, manual/automatic switching, remote start, data recording, etc. Users can achieve quick operation through the buttons and indicator lights on the panel, and can also set parameters, view status and track operation data through the touch screen interface. Some systems support RS485 communication interface or 4G module, which can be connected to the smart fire protection platform to realize remote status monitoring, operation record storage, fault warning push and other functions. In this way, fire protection system managers no longer need to rely on on-site inspections, and can grasp the operating status of the equipment in real time on the control center or mobile phone APP, which greatly improves the operation and maintenance efficiency and management level. In addition, the electric control system is equipped with multiple protection mechanisms, including short-circuit protection, overload protection, phase loss protection, low voltage alarm, automatic reset, delayed start and other functions to ensure that the equipment will not burn out, malfunction and other safety hazards under abnormal power or fault conditions.

In terms of fire response speed, the electric fire pump of the integrated control cabinet has excellent starting response capability. After receiving the fire signal, the control system will automatically complete the self-test procedure, start the motor and drive the pump body to operate within a few seconds, quickly increase the water pressure to the set value, and provide a stable water source for the sprinkler system, indoor and outdoor fire hydrants, water cannon systems, etc. Compared with the start-up delay problem caused by the long control line and slow signal transmission of the traditional split pump group, the integrated pump group significantly reduces the start-up time and improves the fire extinguishing efficiency, which is particularly suitable for large public places with strict response time requirements. In the long-term standby state, the system can also maintain extremely low standby power consumption, and cooperate with the battery to maintain the system power guarantee. Once a power outage occurs, it can also switch to the backup power supply startup mode to ensure that “power is available and power is not available”, and to the greatest extent possible to ensure that the equipment can still be put into normal operation under extreme conditions.

In terms of installation and commissioning, the electric fire pump with integrated control cabinet is extremely convenient. Since all components have been assembled, wired and performance tested before leaving the factory, after arriving at the site, it only needs to complete the connection of the inlet and outlet pipes and the power supply to operate, avoiding the risk of failure caused by on-site installation errors. The base adopts a two-way hoisting structure, which is convenient for direct transportation and placement by forklifts or cranes. It is particularly practical in pump rooms with complex installation conditions or limited space. During the commissioning process, technicians can use the control cabinet panel to perform no-load testing, full-load operation, alarm testing, etc. of the entire system to ensure that the equipment meets the design working condition standards before being put into actual use. This “plug and play” design concept saves a lot of construction time and labor costs, while improving the stability and reliability of the system. It is suitable for large-scale integration in standardized projects, such as residential communities, commercial complexes, and large office buildings.

In terms of operation and maintenance, the integrated electric fire pump also shows extremely high maintainability. Since the control cabinet, motor and pump body are centrally arranged, users do not need to go back and forth between multiple equipment areas during daily inspections. They only need to check the control system alarm records, pump body operation time, current and voltage changes, temperature changes and other parameters in one stop, which greatly improves the efficiency of daily inspections. At the same time, the pump body design reserves maintenance windows and replacement space. Routine maintenance such as cleaning filters, replacing seals, and lubricating bearings can be completed on-site without overall dismantling, reducing interruptions caused by downtime. Some models also support remote fault diagnosis. When the system is abnormal, the device status data can be uploaded through the cloud platform, and remote engineers can assist in locating the problem and giving maintenance suggestions, thereby reducing the problem escalation and processing delays caused by the absence of professional technicians on site.

Since the electric fire pump itself is powered by electricity, it does not require a fuel system or exhaust device, so it is also more environmentally friendly. It has no exhaust gas emissions, low noise and little pollution during operation, and is very suitable for use in buildings with dense traffic, closed space or high air quality requirements, such as hospital wards, underground garages, conference centers, high-end residences, etc. At the same time, its high-efficiency motor can achieve continuous and stable water supply, and will not cause energy waste during the no-load standby stage of the fire protection system. With the intelligent control system, users can also set the working mode and running time, so that the equipment can assume auxiliary functions such as pressure stabilization and water replenishment under non-fire protection conditions, further improving the utilization rate of the equipment.

Overall, the electric fire pump with integrated control cabinet is gradually becoming a standard configuration in modern building fire protection systems with its compact structure, rapid start-up, stable operation, intelligent control, simple maintenance, energy saving and environmental protection and other performance advantages. It not only shows excellent responsiveness when responding to sudden fires, but also shows good controllability and efficiency in daily management. For design units, this type of equipment can significantly simplify the design of fire protection system drawings; for construction units, it reduces the complexity of pipeline layout and construction; for user units, it can reduce operation and maintenance costs and improve the safety factor of use. In the future, with the development of smart buildings, green buildings and digital fire protection, the application of integrated electric fire pumps will be more extensive. As an important part of the building lifeline system, it will play a greater role in protecting the safety of personnel and property.