Home » Other Products » Cooling Efficiency Redefined: Exploring Advanced HVAC Pump Systems

Cooling Efficiency Redefined: Exploring Advanced HVAC Pump Systems

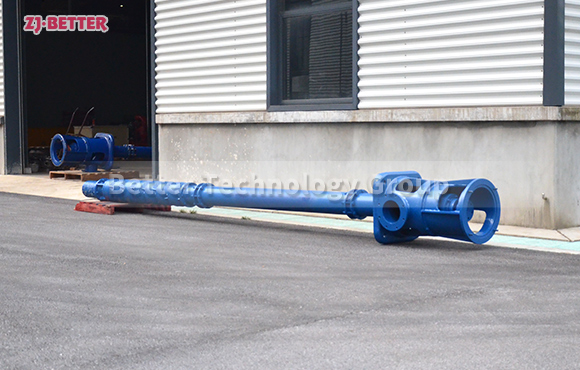

The air conditioning pump system is an indispensable part of modern HVAC systems, regulating the temperature within a building by circulating hot or cold water, providing a comfortable indoor environment. This article delves into the product features of air conditioning pump systems, helping you understand their significance and how to optimize the heating, ventilation, and air conditioning efficiency of your building.

Contact US

Get Price

Share:

Content

Product Features

- Versatility: Air conditioning pump systems not only provide heating but also cooling and ventilation. This versatility makes them a versatile tool for controlling indoor temperature and humidity.

- Precise Temperature Control: Modern air conditioning pump systems use highly accurate temperature sensors to achieve precise control of indoor temperatures, ensuring comfort at all times.

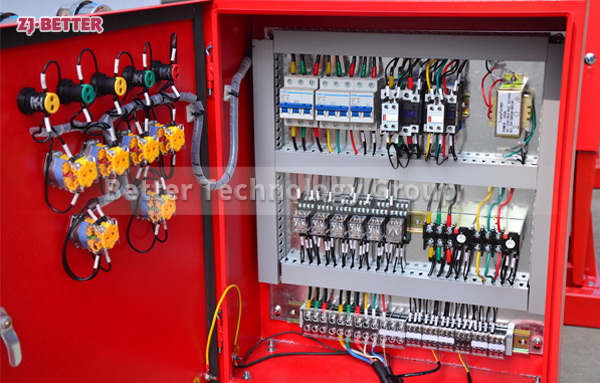

- Energy Efficiency Features: These systems are often equipped with energy-saving features such as variable frequency drives, minimizing energy consumption and reducing operational costs.

- Maintenance and Monitoring: Regular maintenance and monitoring are crucial to keeping the system running smoothly. This includes cleaning and maintaining pumps, replacing key components, and ensuring the performance remains uncompromised.

- Water Quality Management: Maintaining water quality is essential for the long-term operation of the system; hence, water quality monitoring and treatment are integral.

- Safety: Air conditioning pump systems must comply with relevant safety standards and regulations to ensure the safety of both operators and the building.

- Automation Control: Integration with building automation systems allows remote monitoring and control of the system, enabling adjustments based on real-time needs for added convenience.

Inquiry

More Other Products