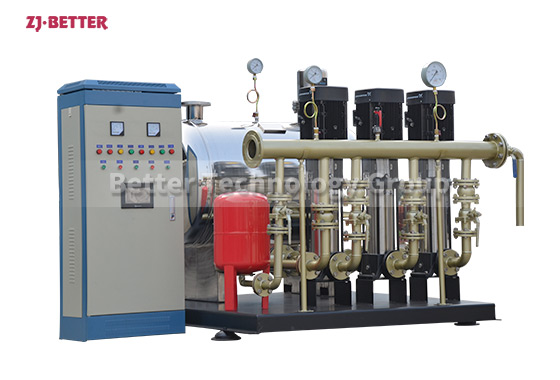

Custom Fire Pump Control Cabinet

The electrical control cabinet of the fire pump set has the switching control mode of single pump, multiple pumps, and multiple main and standby pumps. According to the power of the pump and user requirements, the starting mode of the pump motor can be configured as direct start, star-delta start and other forms.

1. Fully automatic inspection and firefighting function During the whole inspection process, the firefighting inspection cabinet will automatically exit the inspection and encounter a hot situation.

2. Alarm and maintenance function It also has an alarm and maintenance function, which can be used for short-circuit fault, over-current fault and motor power failure. Fault noise occurs throughout the guard inspection process and throughout the alarm system. The alarm device has a fault storage function, which can record the fault content and time.

3. Real-time monitoring function According to customer requirements, the fire patrol cabinet can be equipped with a real-time monitoring module, which communicates with the fire control center according to the system bus to monitor the operation of the system software of the fire control center.