In modern fire safety engineering, the reliability and efficiency of fire pumps are critical to the effectiveness of early-stage fire suppression. As a vital component in water supply systems, single-stage centrifugal pumps have gained wide application in various fire protection systems due to their compact structure, high transmission efficiency, and reliable performance. This article presents an in-depth analysis of the technical strengths of single-stage centrifugal pumps from structural design to operational performance, energy efficiency, installation flexibility, and long-term maintenance benefits.

A single-stage centrifugal pump consists primarily of a single impeller and casing. Compared to multi-stage pumps, its structure is simpler, reducing mechanical losses and manufacturing costs while also making maintenance easier. In fire scenarios, where response time is a crucial metric, the fast startup and quick stabilization of single-stage centrifugal pumps enable immediate water delivery, significantly improving emergency response.

From a hydraulic design perspective, the impeller of a single-stage pump is often optimized using CFD simulations. The wide flow channels and reduced fluid resistance allow for large flow capacities with minimal power consumption. This is particularly essential in high-rise buildings, shopping malls, industrial plants, and other environments requiring high pressure and volume. Whether deployed in wet-pipe systems or dry standpipe networks, single-stage centrifugal pumps offer continuous, reliable water flow.

In terms of material adaptability, single-stage centrifugal pumps can be customized using cast iron, stainless steel, bronze, and other alloys depending on corrosion resistance, pressure tolerance, and temperature requirements. This material versatility extends the service life of the pump while reducing the frequency and cost of maintenance, making the pump adaptable to urban infrastructure and industrial fire protection scenarios alike.

With respect to energy performance, single-stage centrifugal pumps typically achieve efficiency ratings between 75% and 85%. This high efficiency means more water is delivered for the same motor power, which translates to reduced operational costs and supports green building certifications. Fire protection systems aiming to meet energy-saving targets find these pumps particularly attractive.

Installation-wise, single-stage pumps are available in horizontal close-coupled or base-mounted configurations, allowing for customization based on pump room layout, piping direction, and space availability. Their standardized flange interfaces ensure seamless connection with diverse piping systems, simplifying installation, shortening construction timelines, and facilitating system upgrades.

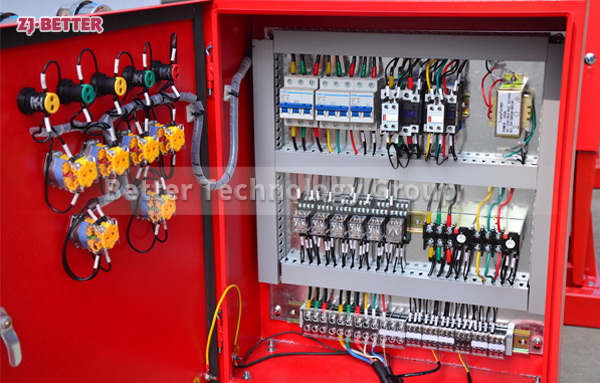

From a control integration standpoint, these pumps can be paired with smart controllers, pressure sensors, and variable frequency drives. The intelligent control system automatically adjusts pump speed according to pressure demand, ensuring on-demand supply while avoiding pressure surges and pipe vibration, thereby enhancing system reliability and service life.

In practical applications, single-stage centrifugal pumps are used extensively in municipal water supply, commercial buildings, underground garages, and industrial zones. For example, in a large shopping center project, the pump was used as the main firewater delivery system. By integrating with a variable-frequency control system, it achieved constant pressure supply with 24/7 readiness, reducing annual electricity consumption by over 20%.

From a maintenance perspective, the simplicity of the pump’s structure and the minimal number of components translate to low maintenance costs. Routine tasks such as replacing seals and bearings or inspecting the impeller are straightforward. Standardized spare parts further facilitate quick repair and minimal downtime.

In conclusion, single-stage centrifugal pumps—due to their efficiency, durability, and adaptability—have become essential components in modern fire protection infrastructure. They significantly enhance system responsiveness, ensure stable water delivery, and optimize energy use. As the demand for smart, efficient, and eco-friendly fire systems continues to rise, single-stage centrifugal pumps will undoubtedly play a pivotal role in the next generation of fire protection engineering.