The Critical Role of Pressure Tanks in Fire Protection Systems

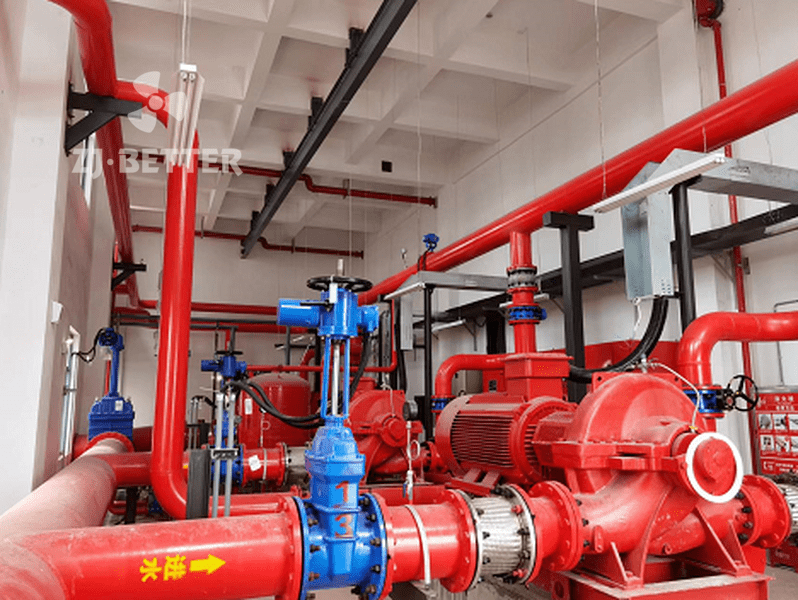

In modern buildings and industrial fire protection systems, pressure tanks play a vital role. Acting as a stabilizer of water pressure, they are essential in ensuring the rapid start-up of fire pumps and providing immediate water supply when every second counts. By storing pre-charged air and water, the pressure tank creates a buffer that prevents water hammer, protecting the system and extending the lifespan of pipes and pumps.

Moreover, before the fire pump is activated, the pressure tank can instantly release stored water, meeting initial firefighting demands and buying valuable time to control early-stage fires. High-quality pressure tanks are usually constructed from corrosion-resistant carbon steel or stainless steel, built for durability and high pressure. They also integrate seamlessly with automated control systems, making them suitable for high-rise buildings, industrial zones, and logistics centers.

A reliable and efficient pressure tank is an indispensable component in any comprehensive fire protection strategy.

This is a modern enterprise specializing in the research, development, and manufacturing of fire pump systems, committed to providing high-performance and intelligent firefighting pump solutions worldwide. The product range includes electric fire pumps, diesel engine fire pumps, pressure stabilization equipment, control systems, and a variety of essential components. These systems are widely applied in industrial plants, high-rise buildings, commercial complexes, and logistics facilities.

Equipped with advanced manufacturing equipment and rigorous testing platforms, the company operates under a strict ISO quality management system and boasts a professional R&D team. Through continuous innovation and technical upgrades, it delivers safer, more efficient, and more reliable fire water systems—earning the trust and praise of clients from Asia, Europe, the Middle East, and Africa.