Corrosion-Resistant and Pressure-Rated: Choosing the Right Pressure Tank for Demanding Sites

This pressure tank, designed for fire protection systems, is made of high-strength carbon steel or stainless steel with excellent corrosion and pressure resistance. It is ideal for complex environments such as high-rise buildings, underground garages, and warehouses. The tank supports various custom sizes, features a compact structure, and allows for easy maintenance. Working in tandem with fire pumps, it ensures constant pressure and rapid response, making it an optimal choice for enhancing fire system reliability and efficiency.

In modern fire protection systems, the pressure tank has become an indispensable core component, especially in the initial water pressure to ensure that the system automatically starts the pump in the link, plays a vital role. Selecting a suitable pressure tank can not only improve the system response speed, but also effectively reduce maintenance costs and accident risks. This article will be “corrosion and pressure resistant design” as the core, in-depth discussion in all kinds of complex working conditions, how to choose a truly high-performance pressure regulator tank for fire protection.

Advantages of product structure and material

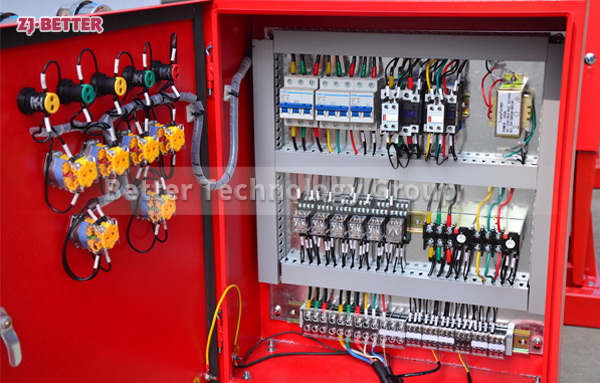

Our recommended pressure tanks are made of high-strength carbon steel or stainless steel, with internal and external anti-corrosion coating, which can effectively resist moisture, water corrosion and external environmental influences. This design significantly extends the service life of the product, especially suitable for high humidity, corrosion-prone industrial or coastal areas. The pressure element part adopts high-precision pressure gauge and imported solenoid valve to ensure accurate control and stable performance.

Core performance characteristics

1. Superior high-pressure resistance: the tank has undergone high-pressure testing and can withstand up to 1.6MPa working pressure, ensuring stable operation under high-intensity operation.

2. Rapid replenishment of pressure, maintain constant pressure state of the water system: linkage with the fire pump operation, effectively reduce the false action or start-up delay, to ensure that the system is always on standby.

3. Various specifications available, support customization: from 50L to 2000L, to meet the needs of different buildings and project size.

4. Convenient maintenance and easy operation: modular structure facilitates daily inspection and maintenance, and the standardized electrical interface is suitable for mainstream control systems in the market.

Recommended Application Scenarios

The pressure tank is widely used in high-rise buildings, airports, warehousing and logistics centers, underground garages, chemical plants and many other fire protection systems require strict scenarios. It is not only suitable for wet systems, but also compatible with dry, pre-action and water spray systems, reflecting a high degree of versatility and compatibility.

Suggestions for selection

When purchasing supporting equipment for fire protection systems, pressure tank products with corrosion-resistant design and high-pressure tolerance should be prioritized, taking into account the use environment, piping design, water supply form and other factors. The safety and response efficiency of the system can be significantly improved by selecting the appropriate pressure tank solution.

.jpg)