Home » Other Products » Functions of fire pump control panel

Functions of fire pump control panel

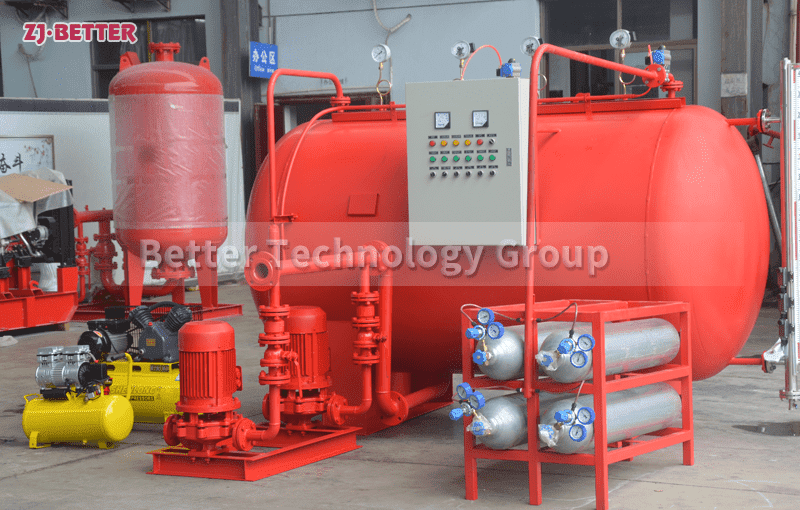

The electrical control cabinet of fire pump set mainly has the functions of starting and stopping the pump, switching between main and standby pumps, manual and automatic switching, dual power switching, patrol inspection, protection, and feedback for mechanical emergency start.

Contact US

Get Price

Share:

Previous:

Eight Custom Fire Pumps

Content

1. Start and stop pump function. The control cabinet is equipped with a button for manually starting and stopping each fire pump, and is equipped with an input terminal for remotely controlling the start of the fire pump. The indicator lights and instruments corresponding to the start and stop of the fire pump should display normal.

2. Main and standby pump switching function. When the main pump fails, the standby pump will be put into operation automatically with a delay. The start-up time of the water pump should not exceed 2 minutes.

3. Manual and automatic conversion function. In the automatic state, the water pump can be started automatically or manually remotely, and the multi-line control panel can stop the water pump remotely. In the manual state, the pump can be started and stopped by the start-stop button of the control cabinet.

4. Dual power switching function. The control cabinet should have dual power supply automatic switching function. The power supply used by the fire pump should be fire power supply, and the dual power switching device can be installed near the electrical control cabinet of the fire pump group, or it can be installed in the electrical control cabinet of the fire pump group.

5. Inspection function. The control cabinet has the functions of regular automatic inspection and manual inspection. The high-power fire pump can use frequency conversion operation to reduce the impact on the power grid and pipe network when the pump is started.

6. Protection function. The control cabinet should have the functions of overload protection, short circuit protection, overvoltage protection, phase loss protection, undervoltage protection, and overheat protection. If the above conditions occur, the fault light of the electrical control cabinet of the fire pump unit will always be on and a fault signal will be sent out.

Inquiry

More Other Products