Diesel Engine-Driven Fire Pumps: Providing Stable and Reliable Emergency Power

Our diesel engine-driven fire pump system is designed to provide continuous and reliable hydraulic support in emergency situations. Whether during power outages or in remote areas without access to the electrical grid, this fire pump ensures the effective operation of the fire protection system. The diesel engine delivers powerful performance, supporting the pump system to operate steadily in extreme conditions and ensuring rapid response during a fire.

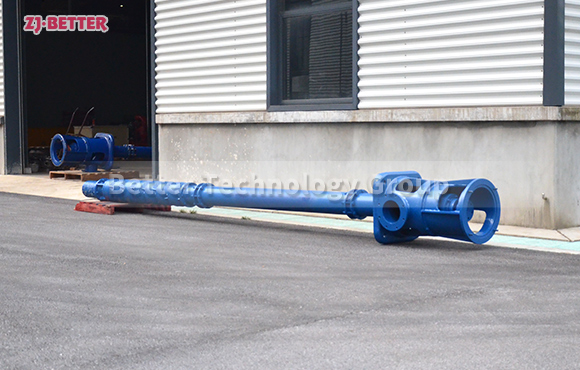

This system combines a high-performance diesel engine with an efficient pump body, offering users exceptional flow and pressure support. It is suitable for various locations, including industrial facilities, commercial buildings, and high-rise residences. Our diesel-driven fire pump also features a compact design for easy installation and maintenance, ensuring long-term high performance.

Additionally, the smart control panel is equipped with features such as automatic start/stop, fault alarms, and remote monitoring, further enhancing the convenience of system management and operation. This fire pump system complies with international fire protection standards, offering stable and reliable quality, making it the ideal choice for ensuring fire safety in buildings.

We are dedicated to providing innovative and reliable fire pump solutions for industries worldwide. Whether in complex industrial environments, bustling commercial buildings, or modern high-rise residences, our fire pump systems deliver outstanding performance, ensuring timely and effective protection of people and property in the event of a fire.

Our fire pump systems combine advanced design concepts with exquisite craftsmanship, utilizing efficient pumps and diesel engine drive configurations to provide powerful hydraulic support. Even in cases of power outages or when the electrical grid cannot supply power, our diesel-driven pumps ensure continuous, stable operation. Particularly in emergency situations, it offers customers a dependable fire protection solution, ensuring reliable performance even in the most challenging environments.

We offer a range of fire pump systems with various configurations to meet the diverse needs of our clients. From large industrial facilities to small commercial buildings, our products meet the fire protection requirements of different industries and applications. Each fire pump undergoes rigorous quality testing before delivery, ensuring compliance with international fire protection standards and providing safe, reliable products.

In addition, we offer comprehensive custom services, including design, installation, and after-sales support. Whether you are building a new project or upgrading an existing fire protection system, our professional team will provide the most optimal solutions based on your specific needs, ensuring long-term, stable operation of your equipment.

Our goal is to help customers enhance fire safety, reduce the risk of fire incidents, and provide comprehensive protection wherever our products are used, through innovation and high-quality solutions.