Home » Other Products » IS end suction pump for CHILLER PLANT EQUIPMENT

IS end suction pump for CHILLER PLANT EQUIPMENT

IS end suction pump, export to Bangladesh. use for CHILLER PLANT EQUIPMENT

Contact US

Get Price

Share:

Previous:

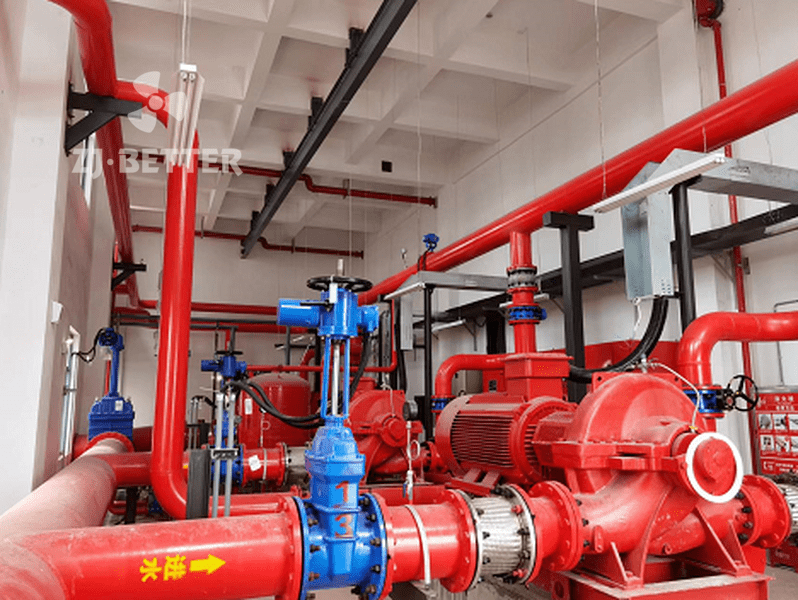

Fire Booster Pump Introduction

Content

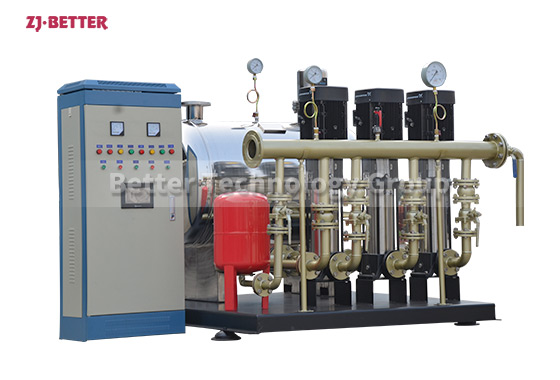

Single stage horizontal mounted end suction Centrifugal type. Pump shall be of Cast Iron casing, base plate, coupled motor, Bronze Impeller, SS shaft, Mechanical seal, saftey cover, vibration isolator with Teco TEFC IP55 squirel cage type 380-415V/3Ph/50Hz/1450 RPM, winding insulstion shall be of class F, IP55 and sevice factor of motor shall not be less than 1.15. Motor mounted on a common base plate. The pump shall be minimum 75% efficient. Motor shall be heavy duty type rated for continuous operation with minimum 15% over rating from BkW as per specification, suitable to operate at 40°C ambient temperature. Pump working pressure 1034 kPa

Inquiry

More Other Products