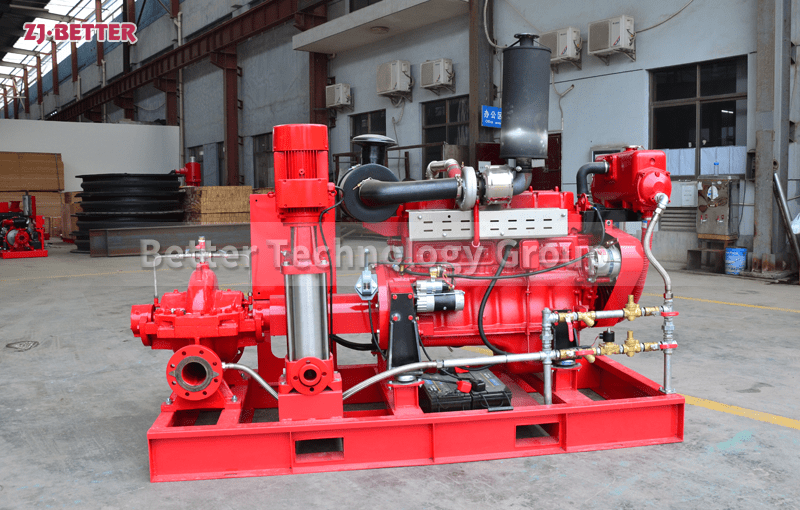

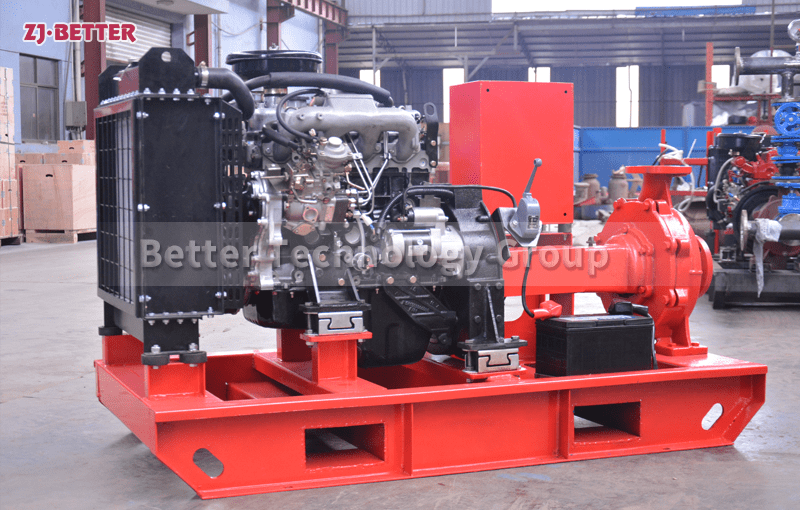

End Suction Diesel Fire Pump

Flow: 80.0-2500 gpm / 5-158 l/s

Head:2-16 bar / 29-232 psi

Caliber: 50-250mm

Power: 3-220kW

Speed: 1500-2600r/min

Working Pressure: 1.6MPa

Product Introduction of XBC-IS series Diesel Fire Pump

ISW series horizontal single-stage single-suction centrifugal pump is a new generation of energy saving, environment friendly horizontal centrifugal pump researched and developed by our company, which absorbs advanced technology of similar products abroad and adopts domestic general performance parameters of centrifugal pumps.

Main Features

1. The pump is the horizontal structure, the inlet and outlet are the same in diameter, and lying in the same center line, which can be

installed in the pipeline as valve, the floor space needed is small, if the protection cover is added, it can be put in the open air.

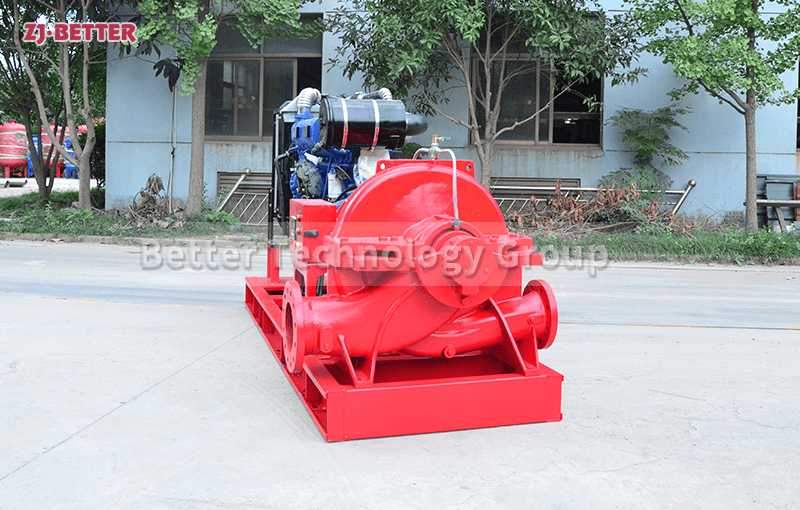

Application Scope

1.Applicable for the XBC series Diesel Fire Pump control made in this Co., and also for the diesel engine fire-fighting pump and diesel generator controls of users.

2.It is applicable for water supply for fire service and emergency water supply.

3.Suitable for the fire-fighting water supply and emergency water supply in storehouse, yard, airport, petroleum and chemical industry, power plant liquefied gas, textile, ship, and oil ship etc. occasions.