The difference between diesel multistage fire pump and single-stage fire pump

Fire pump is a kind of water pump widely used in environmental protection, sewage treatment and fire fighting units. It is similar to the general pump, but its head and total flow are different. And the pump can also be divided into single-stage and multi-stage two forms according to the structure.

The difference between single-stage fire pump and multi-stage fire pump:

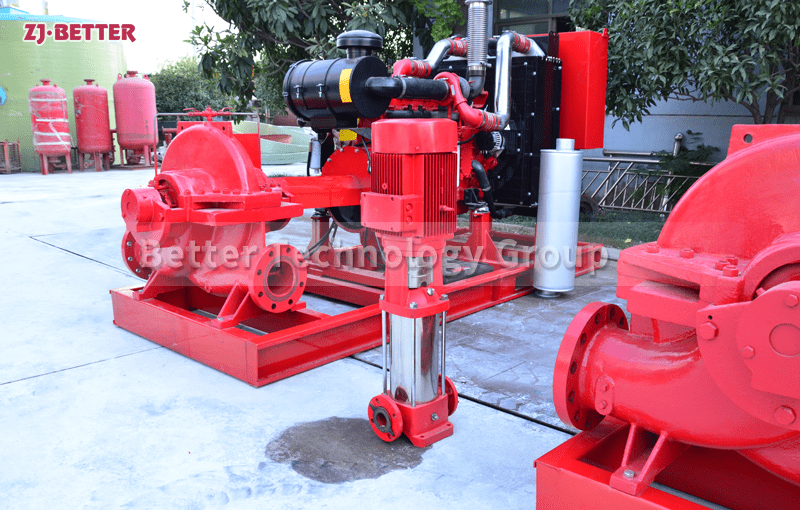

1. The number of impellers is different, and the lift is also different: Generally speaking, a single-stage pump has only one impeller, while a multi-stage pump has two or more impellers, which enables it to absorb water under pressure many times and carry out Segmented processing, which greatly increases the lift. Therefore, under the same medium flow, the lift of the multi-stage fire pump appears higher.

2. The number of motors is different, and the action efficiency is also different: the motor of a single-stage pump is usually only one, while the motor of a multi-stage pump is mixed with two or more, which means that the multi-stage fire pump The power will be greater than a single stage fire pump. Relatively, it is more time-saving than a single-stage fire pump to use, and the scope of use is wider.

3. The curve of the medium flow is different: with water as the basic medium, the water flow curve of the single-stage pump will be relatively uneven. If the pressure increases or the water flow is small, the lift will be very large. In this case, the pressure at the outlet will be too large, or even exceed the load.