Boost Mining Efficiency with Mobile Pump Truck

Explore unparalleled efficiency in mining drainage with our mobile pump trucks. Engineered for adaptability, these cutting-edge solutions guarantee swift water extraction, minimizing downtime and maximizing productivity. Tackle diverse terrain and water levels seamlessly, ensuring optimal performance in any mining operation. Elevate your water management with our innovative and mobile pump trucks – the epitome of mining efficiency.

In the dynamic realm of mining operations, effective water management is paramount for ensuring productivity and safety. Our mobile pump trucks stand as versatile and efficient solutions to address the intricate challenges of mine dewatering.

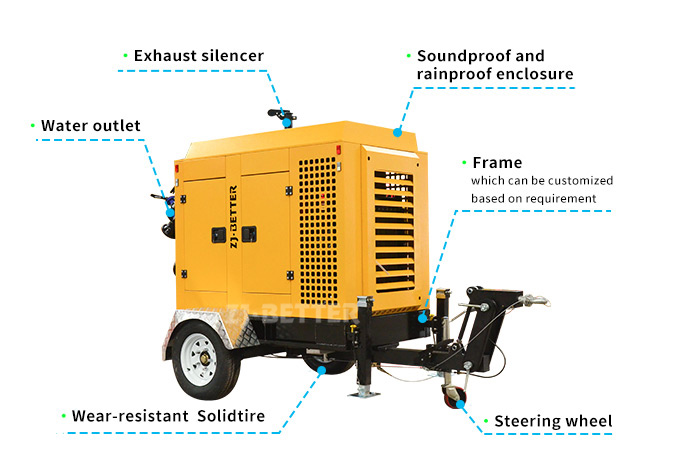

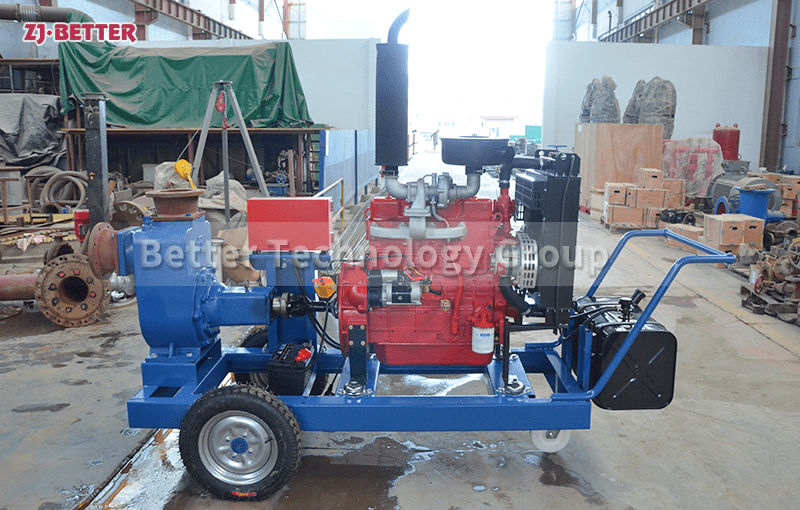

Designed for adaptability, our cutting-edge mobile pump trucks offer a strategic approach to water removal, allowing mining enterprises to swiftly respond to varying water levels and geological conditions. Equipped with state-of-the-art technology, these pump trucks boast powerful pumping capabilities, ensuring rapid and reliable dewatering processes that minimize downtime.

The mobility factor of our pump trucks is a game-changer. With the ability to navigate diverse terrains within the mining site, these vehicles can be swiftly deployed to critical areas, optimizing response times to water accumulation issues. This agility not only enhances operational efficiency but also mitigates potential risks associated with water ingress, safeguarding both personnel and equipment.

Moreover, our mobile pump trucks are engineered with a user-friendly interface, facilitating easy operation by on-site personnel. The intuitive controls enable quick adjustments to water removal rates, ensuring adaptability to changing conditions without compromising safety or efficiency. This user-centric design promotes a seamless integration of our pump trucks into existing mine infrastructure.

The durability and reliability of our mobile pump trucks make them indispensable assets for sustainable mine water management. Built to withstand harsh environmental conditions, these vehicles guarantee longevity and robust performance, contributing to cost-effectiveness over the long term.

Elevate your mine dewatering strategies with our mobile pump trucks—your agile partners in tackling water challenges head-on. Experience the next level of efficiency and reliability as you empower your mining operations with our state-of-the-art solutions.