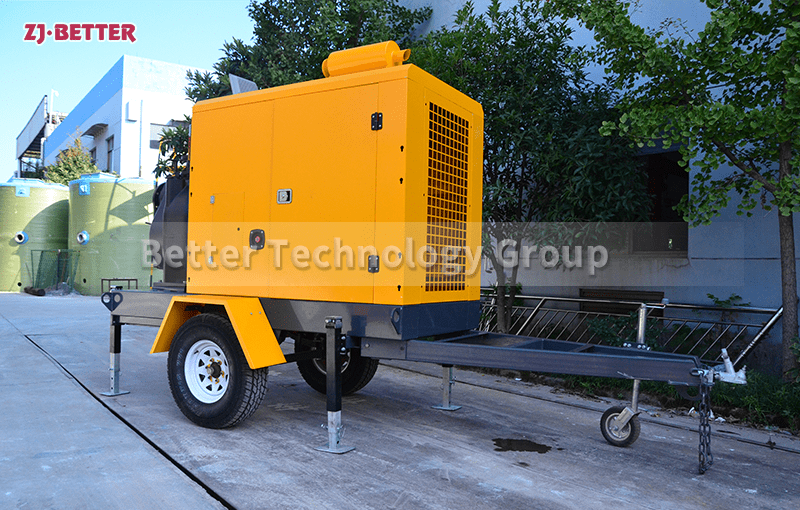

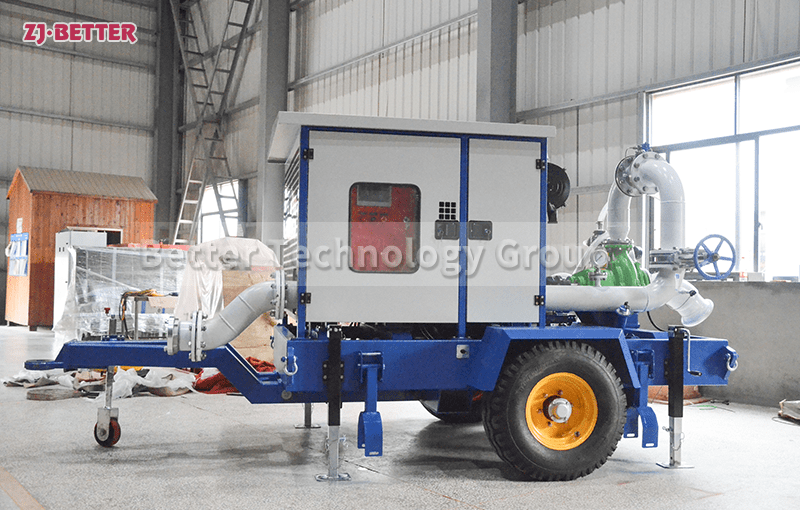

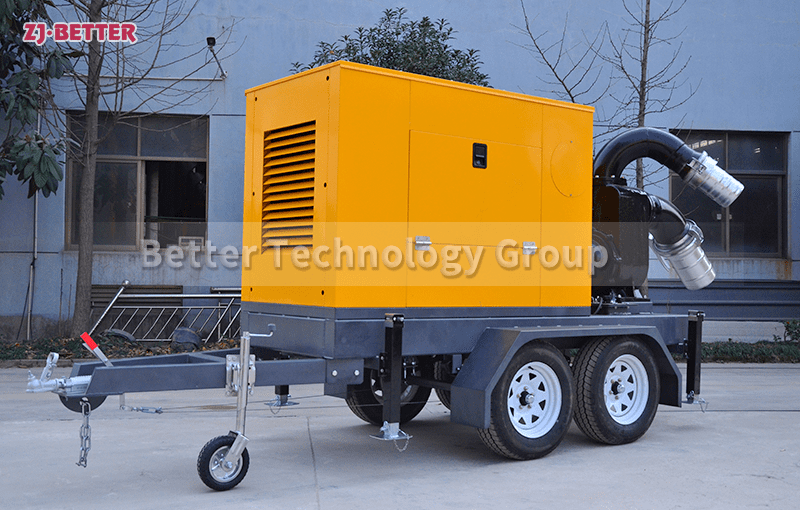

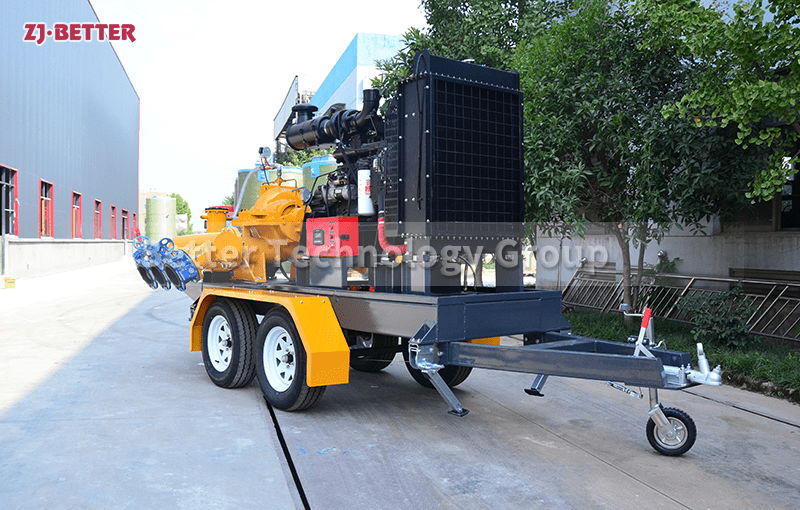

Trailer-Mounted Fire Pump Unit for Easy Transport and Powerful Water Supply

Trailer-mounted fire pump units have the advantages of mobility, large flow output and independent water supply, and are suitable for scenarios such as industrial parks, municipal emergencies, petrochemical bases and disaster relief.

Trailer-mounted fire pump units are essential firefighting equipment designed specifically for rapid deployment and efficient firefighting. They integrate a pump unit, diesel engine, control system, and trailer chassis into a highly flexible, stable, and reliable water supply solution. They play an irreplaceable role in firefighting, temporary water supply, emergency rescue, and other situations where fixed firefighting facilities are lacking. Compared to traditional fixed fire pumps, their trailer-mounted design offers greater mobility, enabling rapid arrival at fire or emergency scenes. They are particularly effective in industrial parks, petrochemical bases, warehousing and logistics centers, municipal water supply systems, and remote rural areas. Their unique advantages and superior performance are making them a preferred choice for many project owners, construction companies, and fire departments. In terms of structural design, trailer-mounted fire pump units typically utilize a rugged chassis with standardized wheels and towing devices, making them adaptable to a variety of transport vehicles and ensuring flexible transport in complex road conditions and emergency situations. The trailer frame is treated with corrosion protection and reinforced to withstand the rigors of frequent transportation and long-term outdoor use, ensuring reliable operation in harsh environments. The pump unit typically utilizes a high-efficiency centrifugal pump, offering high flow, high head, cavitation resistance, and excellent wear resistance. This pump unit can provide sufficient and stable water output within a short period of time, meeting the needs of high-rise buildings, long-distance water delivery, and large-scale firefighting. The engine is typically powered by a diesel engine, characterized by low fuel consumption, high durability, and long maintenance intervals. This self-powered pump unit is particularly valuable in areas without electricity or on temporary construction sites, as it can operate continuously without relying on a mains power supply, significantly enhancing emergency response capabilities and applicability. Regarding the control system, trailer fire pump units are equipped with an intelligent control cabinet, integrating startup, shutdown, operation monitoring, and alarm functions. The intuitive user interface allows users to easily monitor the unit’s operating status. Select models also support automatic switching and remote monitoring, further enhancing ease of use and reliability. The control system monitors key parameters such as water pressure, water flow, and engine speed in real time, ensuring the pump unit can respond quickly and maintain efficient operation in emergency situations. The equipment also features exceptional safety features, including leak prevention in the fuel system and short-circuit and overload protection in the electrical system. The overall structure complies with international fire safety standards and relevant certification requirements. The trailer-mounted fire pump unit boasts rapid deployment, high-flow output, and long-term stable operation, making it suitable for a variety of applications. For example, it can provide long-term, high-volume cooling and firefighting support for storage tank fires in petrochemical plants, serve as a temporary water supply system to ensure residential water supply during municipal pipeline maintenance, and replace fixed pumping stations to provide continuous firefighting support at construction sites or mining areas. Furthermore, the unit’s mobility enables rapid deployment in the event of water supply disruptions caused by natural disasters such as floods and earthquakes, making it a reliable emergency water supply tool. Regarding maintenance, the trailer-mounted fire pump unit features a rational structure and wear-resistant materials for key components, resulting in long maintenance intervals and simple routine maintenance. Regular checks of the fuel, lubricating oil, coolant, and pump seals based on frequency of use ensure continuous and stable operation, significantly reducing operational costs and failure rates. Thanks to its self-diagnosis control system, potential problems can be detected in advance, further enhancing safety and reliability. Regarding environmental protection, modern trailer fire pump sets have seen significant improvements in diesel engine emissions and noise control, aligning with green environmental trends and minimizing environmental impact, making them suitable for use in urban and residential areas. Overall, trailer fire pump sets offer significant advantages in terms of flexibility, high water supply capacity, high independence, ease of operation, safety, reliability, and wide applicability. They not only meet the needs of various users in industrial, commercial, municipal, and rural settings, but also excel in challenging environments, making them an indispensable component of modern firefighting and emergency water supply systems. Whether in routine fire drills or during sudden fires and natural disasters, trailer fire pump sets, with their efficient performance and stable quality, provide a solid safeguard for the safety of life and property. As firefighting equipment continues to evolve towards greater efficiency, intelligence, and convenience, trailer fire pump sets will play an even more crucial role in future firefighting systems, becoming a preferred emergency water supply solution for more users and fire departments.