High-Efficiency Emergency Protection: Performance and Applications of Mobile Diesel Fire Pumps

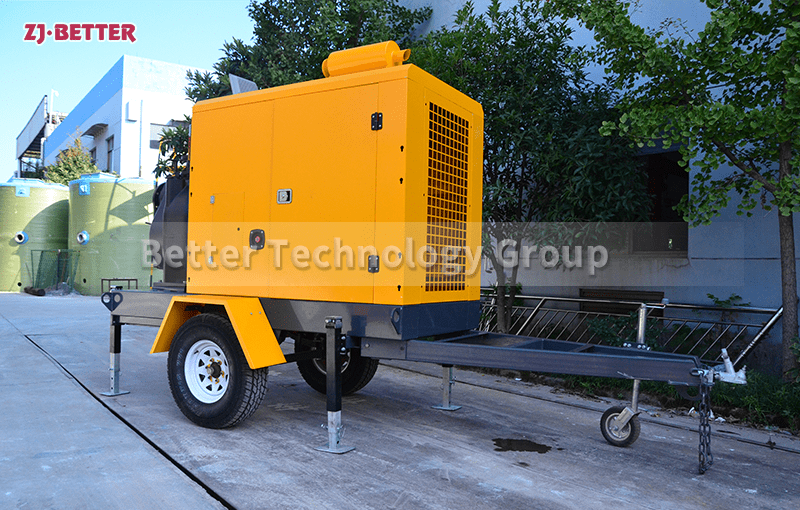

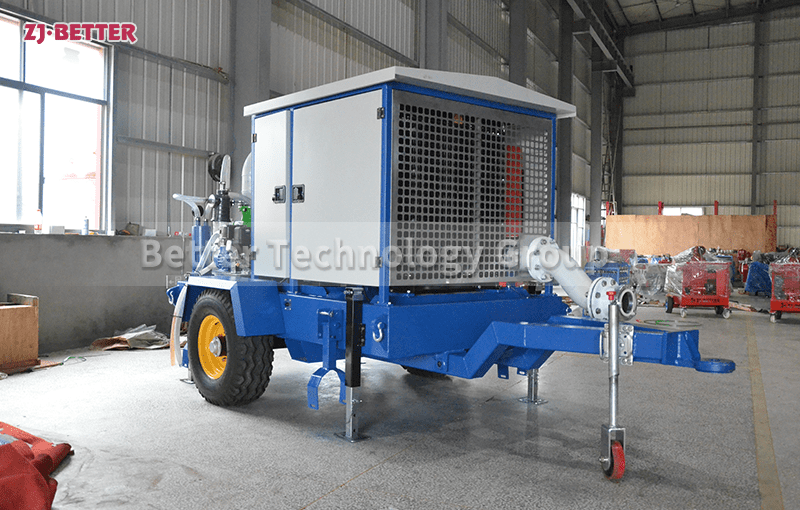

Highly efficient and mobile diesel-powered fire pump with independent power source, high flow rate, high head, and strong adaptability, suitable for rapid water supply and firefighting needs in urban blind spots, remote areas, ports, oil depots, and other scenarios, ensuring efficient and safe emergency rescue operations.

High-Efficiency Emergency Response — Performance and Applications of Mobile Diesel-Powered Fire Pumps Mobile diesel-powered fire pumps are specialized firefighting equipment that combine mobility, efficiency, and reliability. They are widely used in urban firefighting, industrial parks, warehousing and logistics, ports and terminals, airports, oil depots, chemical plants, and areas lacking fixed firefighting facilities. These pumps can be rapidly deployed in the event of a fire or emergency to ensure the safety of lives and property. Powered by a diesel engine, it operates independently without requiring an external power source, making it particularly suitable for tasks in power outages, remote areas, or harsh environments, truly achieving efficient emergency fire protection. The core advantage of this equipment lies in its mobility and flexibility. Due to its mobile design, the entire unit is typically mounted on a wheeled chassis or trailer, enabling it to be quickly transported to the scene via manual pushing or vehicle towing, significantly reducing fire response times. In areas with complex terrain or limited access conditions, this mobility is particularly important, enabling the system to bypass obstacles and deliver water directly to the fire scene at close range, effectively enhancing firefighting efficiency. Additionally, the diesel engine-driven high-efficiency power system ensures robust output even in the absence of electricity, guaranteeing continuous operation of the fire pump. High-quality diesel engines feature quick startup, ample power, high torque, and low fuel consumption, making them suitable for prolonged, high-load operational environments. Additionally, diesel engines are heat-resistant, moisture-resistant, and highly adaptable, maintaining stable performance in extreme conditions such as extreme cold, high temperatures, and dusty environments, ensuring reliable operation when it matters most. The pump body features an efficient hydraulic design with appropriately matched inlet and outlet diameters. The impeller undergoes dynamic balancing, ensuring smooth operation with minimal vibration. It delivers high flow rates and head at low energy consumption, meeting the demands of high-rise buildings, long-distance water supply, and high-pressure spraying. Some models are equipped with dual impellers and multi-stage structures, enabling stable water supply under high-pressure conditions and meeting the water supply requirements of various fire protection systems such as sprinklers, fire hydrants, and turrets. To ensure safety during prolonged operation, mobile diesel-powered fire pumps are generally equipped with comprehensive control and protection systems. The intelligent control panel displays real-time operational parameters such as RPM, water pressure, oil pressure, and water temperature, and features automatic alarm and shutdown protection functions. In cases of low oil pressure, high water temperature, or overspeed, protective measures are immediately activated to prevent equipment damage. Additionally, some models support one-button startup and remote control, simplifying operation and enabling non-professionals to operate the equipment quickly. In terms of fuel system design, these fire pumps are fitted with large-capacity fuel tanks, enabling continuous operation for several hours or longer. The fuel tank’s position and structure are designed for convenient refueling and maintenance. The efficient fuel injection and combustion system not only improves fuel efficiency but also reduces emissions and noise, meeting environmental protection requirements. Additionally, the exhaust system incorporates noise reduction and thermal insulation treatments, ensuring the equipment does not cause excessive disturbance when used in noise-sensitive areas such as residential zones or hospitals. The selection of structural materials also prioritizes durability and corrosion resistance. The pump body is typically made of high-strength cast iron or stainless steel, with the inner walls treated with a special coating to effectively resist corrosion and wear. The chassis and brackets undergo anti-corrosion coating treatment, making them suitable for long-term outdoor use, even in coastal areas with high salt fog or high humidity and heat, where they remain reliable in performance. The overall structural layout is compact, facilitating transportation, storage, and rapid deployment. To meet diverse application requirements, mobile diesel-powered fire pumps typically offer multiple specifications for flow rate and head. Flow rates range from several dozen cubic meters per hour to hundreds of cubic meters per hour, while head coverage spans low-pressure, medium-pressure, and high-pressure ranges. Users can select the appropriate model based on actual application scenarios. Some products also support parallel or series operation to achieve higher flow rates or pressure, making them ideal for large-scale firefighting or long-distance water supply tasks. In terms of applications, mobile diesel-powered fire pumps are not only suitable for areas inaccessible to urban fire trucks but are also commonly used for temporary fire protection at large-scale events, dust suppression and drainage at construction sites, and emergency drainage during flood disasters, offering multi-functional value. In high-risk areas such as ports, oil depots, and chemical plants, they can be deployed as independent firefighting units to minimize losses caused by fire spread. In scenarios such as warehousing and logistics parks, agricultural irrigation, and flood control and drought relief, it can also play a crucial role. Notably, the maintenance and upkeep of such equipment are relatively simple, as the engine and pump components are standardized designs, and wear-prone parts are easy to replace. Routine inspections only need to focus on the status of fuel, lubricating oil, coolant, and the filtration system, thereby reducing operational and maintenance costs. To ensure long-term stable operation, it is recommended to conduct comprehensive inspections and test runs at regular intervals to ensure reliability during critical moments. From a market trend perspective, as demands for firefighting emergency capabilities continue to rise, mobile diesel-powered fire pumps are evolving toward smarter, more environmentally friendly, and more efficient designs. For example, new-generation products are integrating GPS positioning, wireless remote monitoring, and data recording functions to facilitate equipment scheduling and operational management; engine technology is continuously optimized to improve fuel efficiency and emission standards; and pump hydraulic design is continuously improved to achieve higher energy efficiency ratios. This not only enhances the equipment’s overall competitiveness but also further meets the modern firefighting and emergency rescue demands for rapid response and high reliability. In summary, mobile diesel-powered fire pumps, with their independent power source, robust performance, flexibility, ease of operation, and strong adaptability, are an ideal choice for addressing various fire and emergency situations. Whether it is rapid water supply in urban fire blind spots or independent firefighting tasks in remote areas, it can leverage its efficient water supply capabilities and reliable operational performance to gain valuable time for fire rescue operations, thereby minimizing casualties and property losses. In the future emergency firefighting equipment system, such equipment will continue to play an indispensable role, providing a solid foundation for public safety.