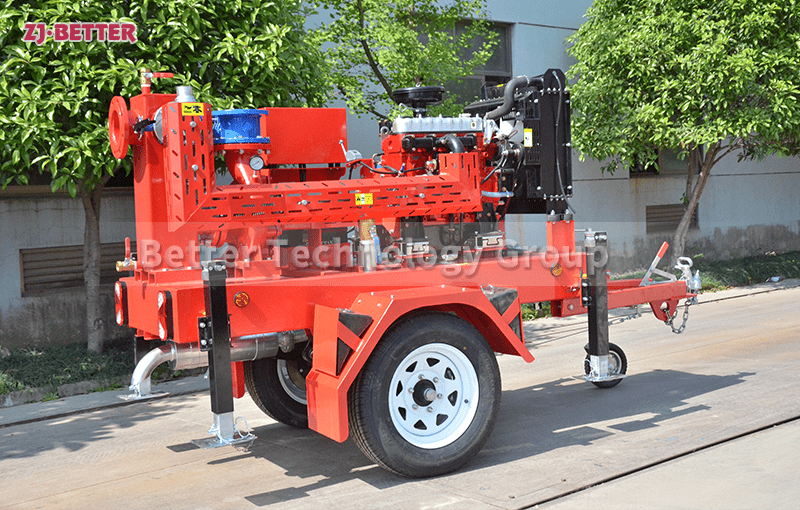

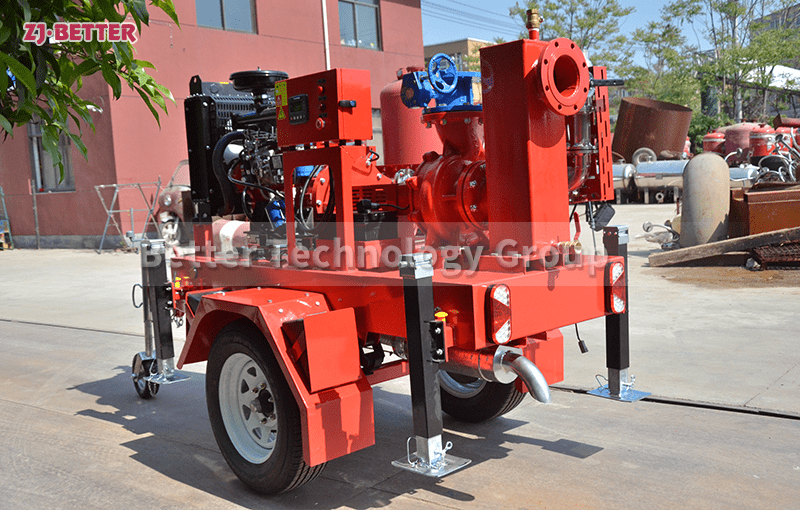

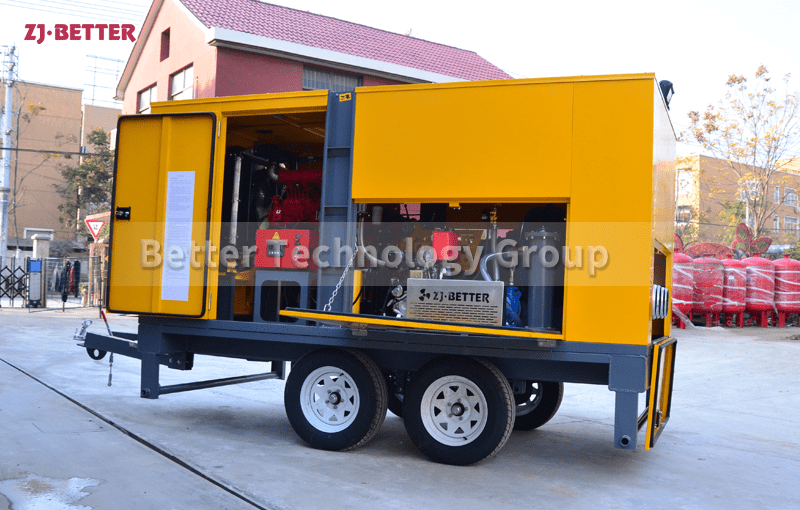

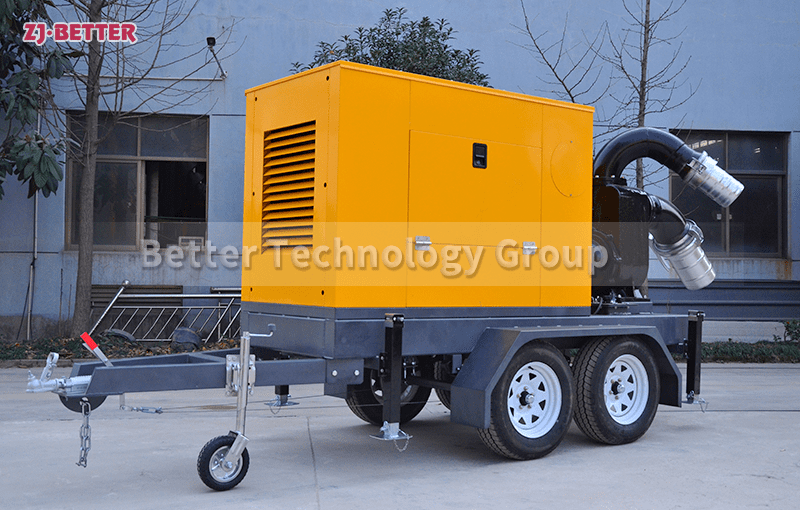

Multi-Purpose Diesel Engine Driven Fire Pump Trailer – Reliable Equipment for Fire Scene Water Supply

The multi-purpose diesel engine-driven fire pump truck has the advantages of high maneuverability, large flow, high head and independent energy supply. It is suitable for fire water supply in cities, industries, ports and remote areas. It supports one-button start and remote monitoring to ensure efficient and stable water supply for fire emergencies.

The multi-purpose diesel engine driven fire pump truck is a high-efficiency mobile equipment designed to meet various fire fighting and emergency water supply needs. It is widely used in industrial parks, port terminals, storage and logistics areas, urban communities, mines and field operations, and other environments with high flexibility requirements for fire water supply. This type of equipment uses a diesel engine as a power source, does not rely on external power supplies, and has strong self-sufficiency. It can be quickly put into use even in power outages, remote areas or harsh environments to ensure a continuous and stable water supply at the fire scene. The equipment adopts a vehicle-mounted trailer structure with good maneuverability and flexibility. It can be quickly moved to a designated location by vehicle towing, saving precious rescue time. The frame is welded with high-strength steel, with a stable structure and strong shock resistance. It can withstand vibration and impact during long-term operation. It is also equipped with an anti-corrosion spraying process to effectively extend the service life of the equipment. In terms of core power On the other hand, the diesel engine adopts high-pressure common rail, turbocharging and high-efficiency cooling system design to ensure that it can still stably output strong power in high temperature, high humidity and high dust environment. It is equipped with a high-performance centrifugal fire pump to achieve large flow and high lift water supply. The flow range can cover hundreds to thousands of cubic meters per hour, and the lift can meet the needs of high-rise buildings or long-distance water delivery. The pump body and flow-through components are made of wear-resistant alloy or stainless steel, which is corrosion-resistant and wear-resistant, and can adapt to a variety of media such as clean water, lightly sandy water and seawater. The whole set of equipment is equipped with an advanced automatic control system with integrated start-up, monitoring, alarm and protection functions. It can realize one-button start and remote monitoring, and display the operating parameters such as speed, oil pressure, water temperature, pump pressure in real time. It will automatically alarm or shut down for protection in case of abnormality to reduce failure losses. The control panel has a reasonable layout and intuitive operation, which is convenient for on-site personnel to quickly master the use method. The fuel system is designed The design takes into account the needs of long-term continuous operation, is equipped with a large-capacity fuel tank, and has a low oil level alarm and a quick refueling interface to ensure long-term uninterrupted operation. The cooling system adopts a high-efficiency water tank and air cooling combination design to ensure that the diesel engine maintains a suitable temperature during long-term high-load operation to avoid overheating and shutdown. The exhaust system meets environmental protection standards, reducing emission pollution and noise impact. In addition, the equipment’s mobile chassis structure is stable, with support feet and braking devices to ensure stability during work and prevent movement and displacement. The tires are wear-resistant and explosion-proof models that can adapt to a variety of ground conditions to ensure smooth movement on mud, sand or hard roads. The overall design takes into account the needs of rapid deployment and long-term operation. Installation and water supply operations can be completed within minutes. It is widely used in urban high-rise fire fighting, rural and remote areas water supply, industrial fire emergencies, oil depot and chemical area fire fighting, port ship fire fighting and temporary supply of large-scale events Water and other tasks, through flexible configuration solutions, optional foam proportioning system, dual pump switching system or parallel / series water supply mode can be used to cope with different fire extinguishing media and pressure flow requirements. In terms of maintenance, the equipment structure is reasonably laid out, and wearing parts and maintenance parts can be easily accessed and replaced. High-precision coupling transmission is used between the diesel engine and the pump to reduce energy loss and mechanical failure rate. The lubrication system adopts fully automatic circulation lubrication to extend the service life of key components. At the same time, manufacturers usually provide complete training and after-sales service solutions to ensure that users can operate the equipment efficiently for a long time. Overall, the multi-purpose diesel engine-driven fire pump truck has become an important equipment in the field of modern firefighting and emergency water supply with its independent energy supply, high maneuverability, large flow, high head, stability and reliability, easy operation and multi-functional adaptability. It helps to significantly improve the efficiency and success rate of fire fighting and emergency response.