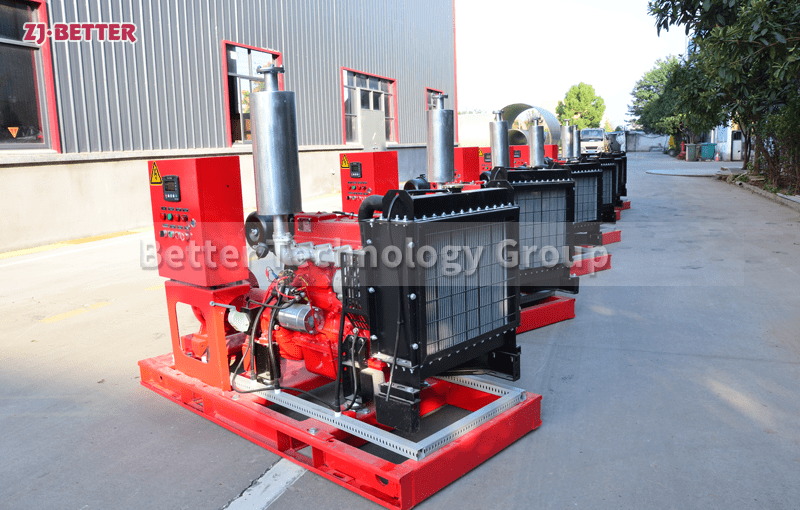

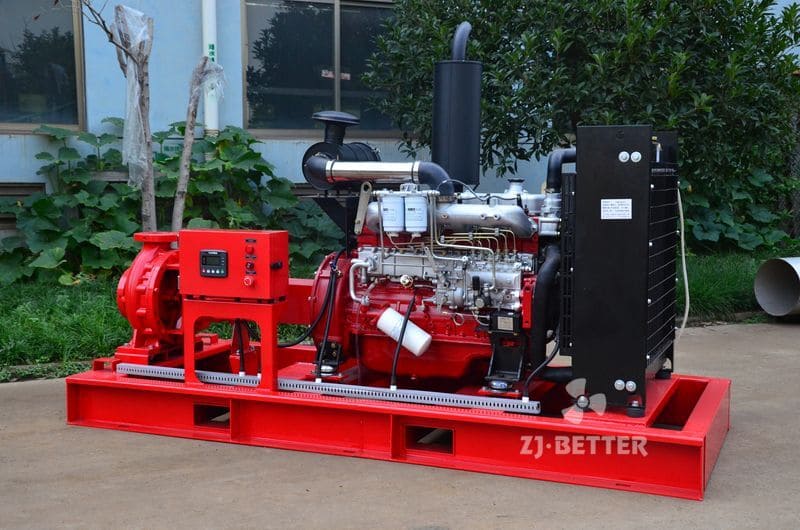

Boosting Fire Safety: Diesel Engine Flow-Mixing Pump

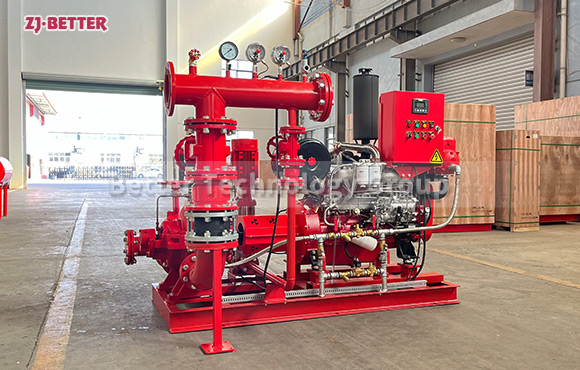

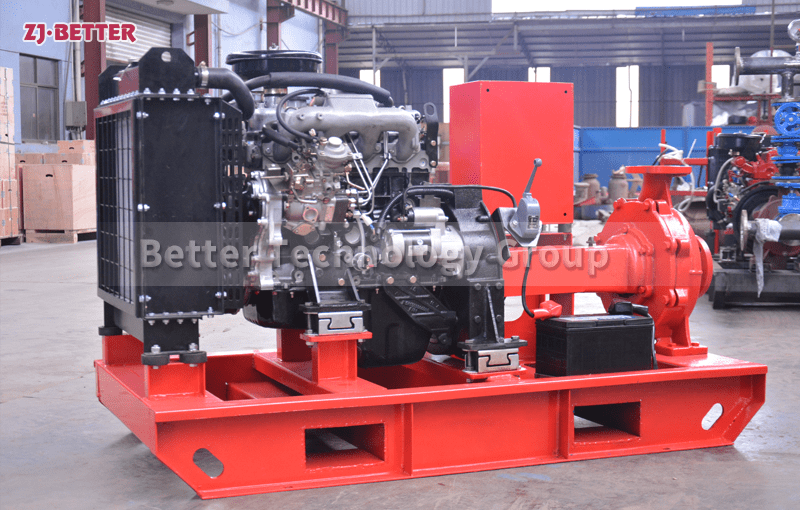

The Diesel Engine with Mixed Flow Pump is an advanced firefighting and rescue equipment. This combination consists of a robust diesel engine and an efficient mixed flow pump, offering advantages such as independent power supply, high performance, agile mobility, versatility, and cost-effectiveness. During sudden fire emergencies, the Diesel Engine with Mixed Flow Pump operates autonomously, requiring no external power source, and rapidly provides a substantial water supply to minimize fire damage. Its exceptional mobility allows firefighters to swiftly transition and address ever-changing disaster scenarios. It is suitable for various environments, especially in areas with unstable power supply, where it maintains its peak efficiency. Moreover, this equipment is cost-effective, easy to maintain, and offers long-lasting firefighting assurance.

Fire disasters strike with sudden and overwhelming force, making it our solemn duty to be prepared. In these critical moments, the Diesel Engine with Mixed Flow Pump emerges as a star performer in the realm of firefighting. This remarkable combination brings together the power of a robust diesel engine and the efficiency of a mixed flow pump, providing an unbeatable rescue duo. Let’s explore the outstanding advantages of this product, ensuring the safety and protection of your home.

1.Agile and Responsive – The First Step in Crisis

The Diesel Engine with Mixed Flow Pump features independent power supply capabilities, eliminating the reliance on external electricity. Even during power outages, this firefighting pump can operate autonomously, ensuring a continuous water source for swift response and containing fires at the initial stage, thus minimizing potential losses.

2. High Efficiency – Rapid Response to Emergencies

The high power and broad speed range of the diesel engine enable the mixed flow pump to operate efficiently, delivering an impressive water flow rate to the fire scene. As a highly efficient and high-flow pump, its response speed and water delivery efficiency are second to none. In critical moments, every second counts, and this high-performing firefighting pump ensures the fastest possible rescue, safeguarding your loved ones and property.

3. Emergency Mobility – Seamless Transitions

Often mounted on mobile vehicles or chassis, the Diesel Engine with Mixed Flow Pump boasts exceptional maneuverability. Firefighters can swiftly transport the pump to the fire scene, overcoming any logistical challenges. Whether fires occur in urban or remote areas, this pump remains agile, ensuring relentless and efficient firefighting operations.

4. Versatility – Comprehensive Protection for All

The strength of the Diesel Engine with Mixed Flow Pump lies in its adaptability to diverse situations. Suitable for various environments, especially in remote areas, or places with unstable power supply, it maintains peak performance. Whether facing forest fires, building incidents, or any unforeseen emergencies, it stands as the ultimate guardian of your home!