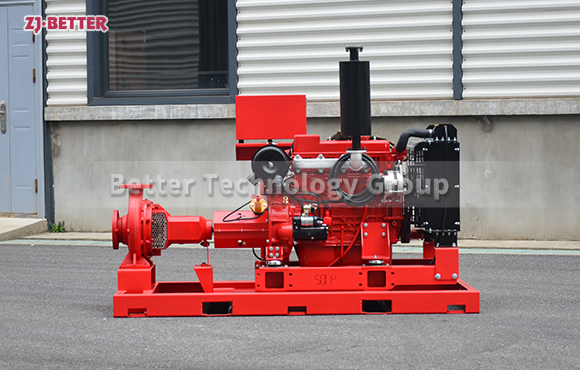

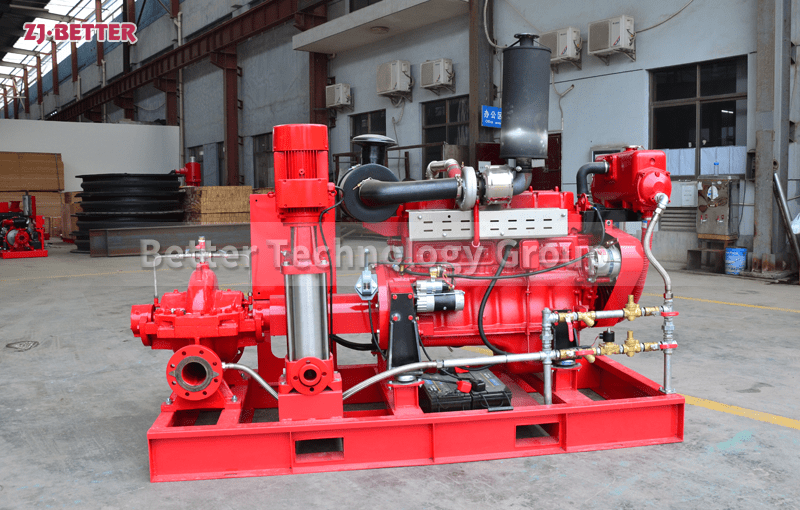

Configuration and Application of Diesel Engine Fire Pump

Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in emergencies such as no power supply or abnormal power supply, it can also be equipped with other diesel engines as power machines according to the needs of users.

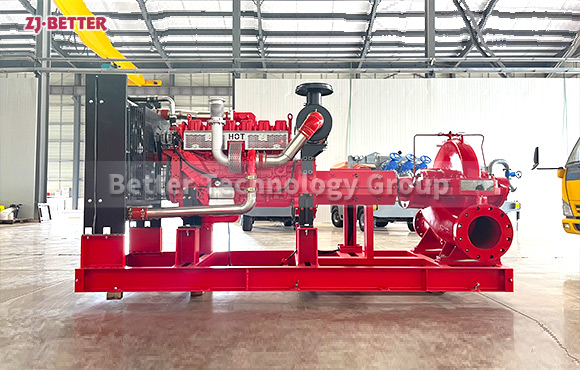

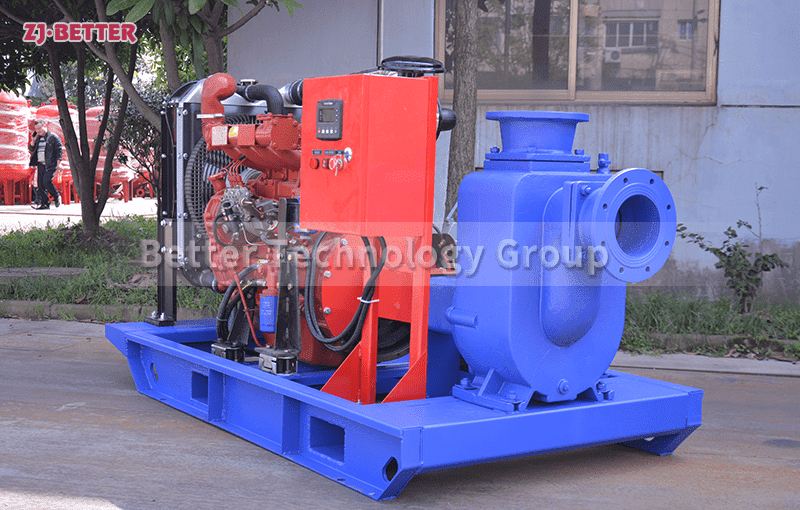

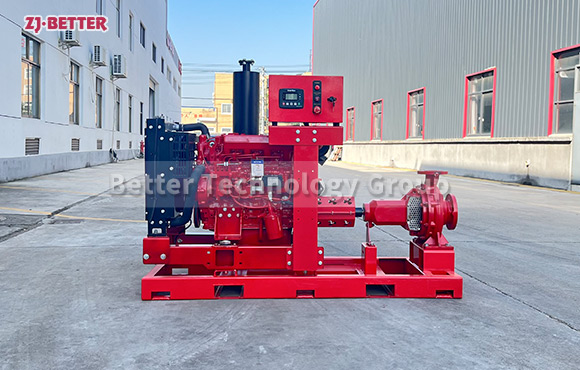

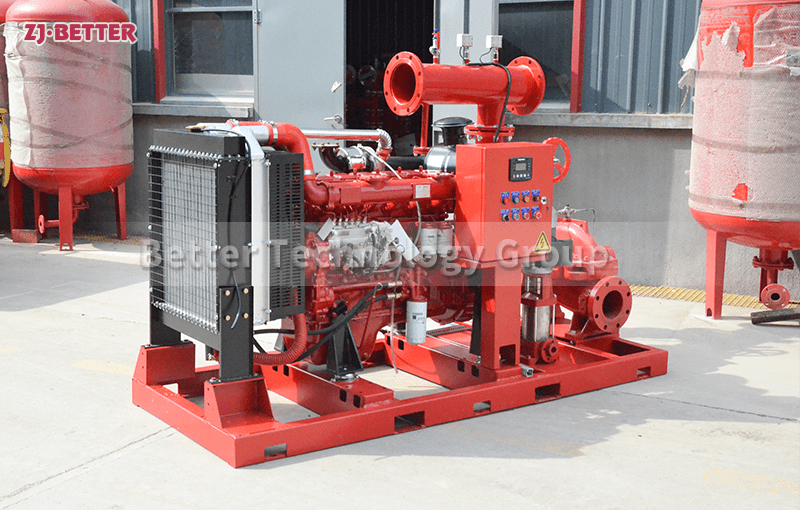

Diesel engine fire pumps have been widely used as fixed fire extinguishing equipment for fire diversion, especially in the case of sudden fire water supply such as lack of power supply or abnormal power supply. , fire pump, connection device, fuel tank, radiator, battery pack, intelligent automatic control screen, etc. Diesel engine fire pump products have the characteristics of leading technology, high degree of automation, excellent performance protection function, reasonable structure, simple installation and high cost performance. At the same time, in order to meet the different needs of users and make reasonable investment, the products are divided into multiple application series such as fire pumps, industrial emergency pumps, agricultural pumps, marine pumps, and trailer-type mobile water pump stations, which can be used together with electric fire pumps.

After receiving fire/pipe network pressure/power failure/other starting signals, the diesel engine fire pump can automatically start within 5 seconds and enter into full-load operation. The battery can be automatically charged by the main power supply or the diesel charging motor to ensure the smooth start of the equipment; the diesel engine will automatically alarm and protect the low oil pressure, high water temperature and other faults, and the overspeed alarm will stop; the diesel engine fire pump will be in the thermal standby state to ensure emergency work. The diesel engine fire pump adopts the direct connection technology between the diesel engine and the water pump. Through the elastic coupling, the failure points are reduced, the start-up time of the unit is greatly shortened, and the reliability and emergency performance of the unit are improved.