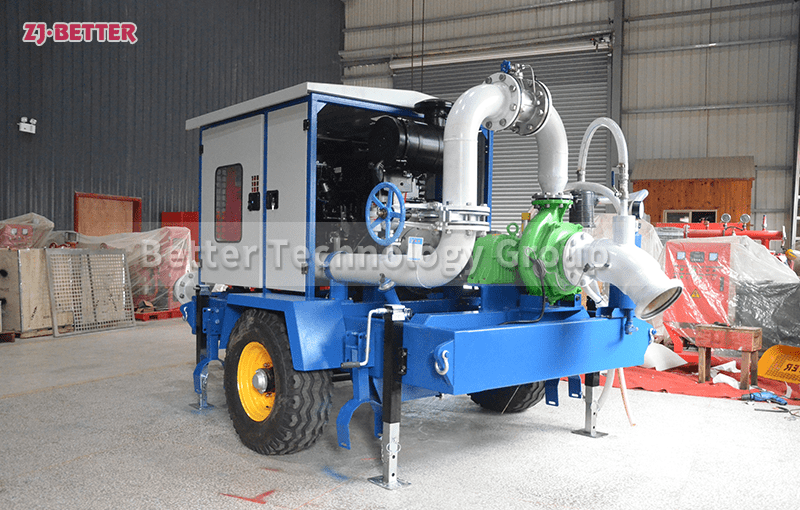

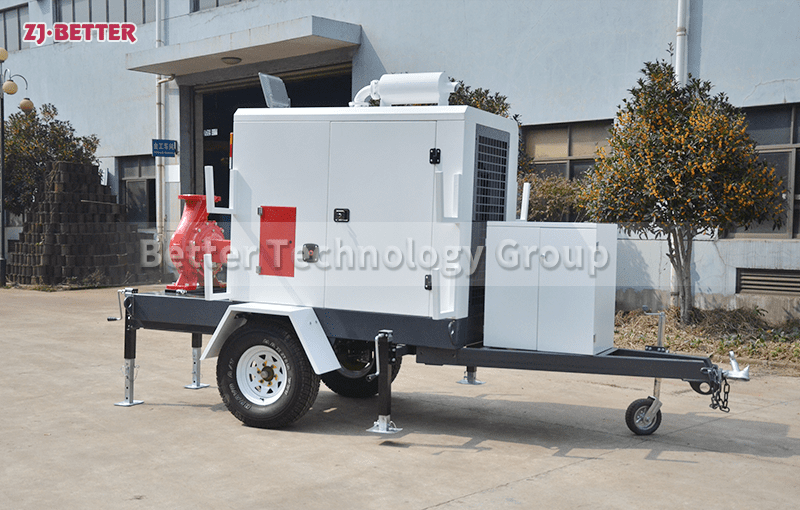

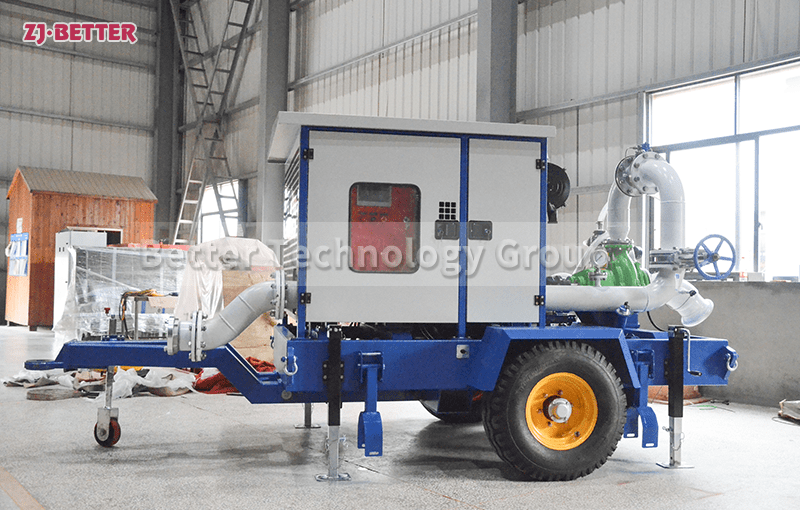

Reliability and Portability: Key Advantages of End-Suction Pump Truck with the ISO 200*150-500 pump

End-Suction Pump Truck with the ISO 200*150-500 pump play a vital role in diverse engineering projects. Their efficient pumping capabilities, flexible mobility, and extensive application areas provide reliable solutions for a wide range of construction projects, whether in building, tunneling, excavation, or mining. As a pivotal asset in the construction industry, End-Suction Pump Truck will continue to drive advancements and progress in engineering. For more information about End-Suction Pump Truck, feel free to contact us at any time.

End-Suction Pump Truck equipped with the ISO 200*150-500 pump boast several outstanding features, including:

- High Pumping Efficiency: The pumps come with robust pumping systems, enabling efficient and stable pumping of materials with varying particle sizes and properties.

- Flexibility and Maneuverability: Designed for compactness, these mobile pumps feature reliable mobility mechanisms, allowing them to adapt to diverse construction site environments, facilitating swift movement and positioning.

- Automated Control: End-Suction Pump Truck utilize advanced automated control systems, ensuring precise control and monitoring throughout the pumping process.

- Durability and Reliability: Constructed with sturdy materials and a robust structure, these pumps exhibit exceptional durability and a prolonged lifespan.

- Multi-Function Adaptability: Suitable for a range of engineering sectors, including construction, tunneling, excavation, and mining, among others.

End-Suction Pump Truck with the ISO 200*150-500 pump find wide-ranging applications in multiple engineering fields, including but not limited to:

- Construction Projects:In high-rise construction, End-Suction Pump Truck efficiently transport concrete to different floors, enhancing construction efficiency.

- Tunneling Projects:These pumps facilitate the pumping of slurry and concrete in tunnel construction, adapting to confined spaces and specialized environments.

- Excavation Projects:In large-scale excavation endeavors, the pumps efficiently discharge excavated slurry, mine tailings, and other materials.

- Mining Industry:End-Suction Pump Truck are used in mining operations to pump ore and tailings, reducing manual labor while boosting production efficiency.