A Reliable Partner for Continuous Operation: Centrifugal Fire Pump in Industrial and Municipal Systems

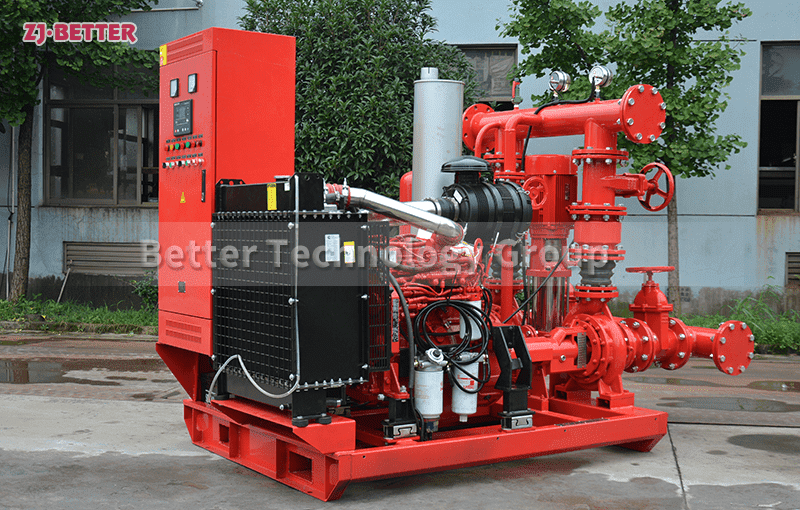

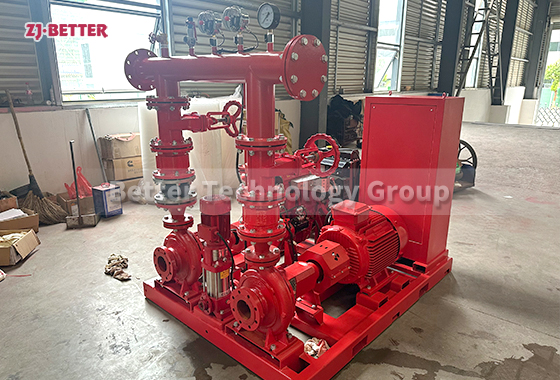

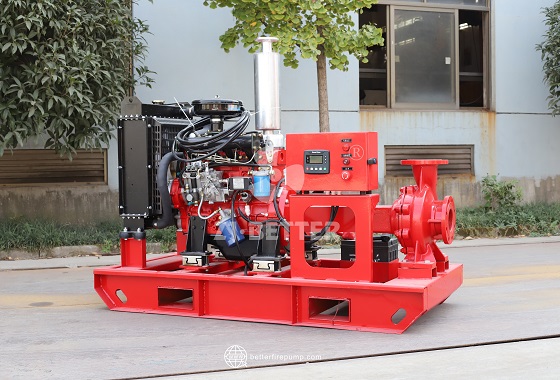

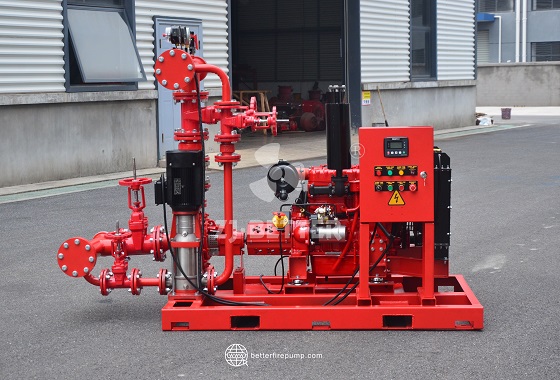

Highly efficient double-suction centrifugal fire pumps offer strong flow output, stable water pressure, and a durable structural design. Suitable for fire protection systems in large industrial facilities and municipal buildings, they are easy to install and cost-effective to maintain, ensuring the reliability and safety of fire water supply, making them an ideal choice for enhancing fire protection system performance.

As core equipment in modern fire protection systems and water supply and drainage projects, centrifugal fire pumps play an irreplaceable role in industrial and municipal systems with their efficient, stable, and reliable performance. These devices convert mechanical energy into fluid kinetic and pressure energy through the high-speed rotation of their impellers, ensuring continuous and stable water supply, safeguarding fire safety and pipe network operations in a variety of environments. Whether in high-rise buildings, large industrial parks, municipal pipe networks, or public infrastructure, centrifugal fire pumps maintain efficient operation over extended periods, demonstrating exceptional reliability at critical moments. Firstly, in terms of performance advantages, centrifugal fire pumps offer high flow rates, low pulsation, and smooth operation, enabling them to maintain stable water output over extended periods of operation, which is particularly important for the continuity requirements of municipal water supply networks and industrial production. Through optimized hydraulic design and high-strength material construction, these devices maintain water supply pressure while reducing energy loss, improving overall operating efficiency, and achieving energy conservation and consumption reduction. Secondly, in terms of structural design, the centrifugal fire pump utilizes a rational hydraulic model and symmetrical double-suction structure, effectively balancing radial forces during operation, reducing bearing loads, and extending service life. Furthermore, the optimized connection structure between the pump body and the motor facilitates installation and maintenance while ensuring long-term stability and tight sealing, minimizing the risk of leakage. Thirdly, centrifugal fire pumps offer outstanding reliability. Core components such as bearings, seals, and impellers are precision-manufactured and rigorously tested to ensure stable performance even under intense operating conditions. In municipal systems, pumps often operate continuously, requiring the equipment to withstand prolonged loads. Centrifugal fire pumps, thanks to their wear-resistant materials and efficient heat dissipation systems, ensure continuous operational reliability. Fourthly, centrifugal fire pumps are highly versatile and can be widely used in industrial cooling systems, water booster systems, fire water supply systems, municipal water networks, and large-scale water treatment projects. They can not only meet the high-pressure water supply demands of high-rise buildings, but also the high-flow and stable water supply requirements of industrial production. Furthermore, in the event of a sudden fire, the pumps can quickly start and provide sufficient water pressure, ensuring a continuous flow of water to support the firefighting system. Fifth, centrifugal fire pumps also offer advantages in intelligent and automated control. Modern products are commonly equipped with intelligent monitoring systems and remote control capabilities, enabling real-time monitoring of the pump unit’s pressure, flow, temperature, and operating status, promptly detecting anomalies and issuing alarms to prevent escalation. This design not only reduces manual inspection costs but also improves the safety and reliability of equipment operation, making it more suitable for the needs of modern municipal and industrial systems. Sixth, in terms of energy conservation and environmental protection, centrifugal fire pumps have been rigorously optimized for efficiency and utilize advanced fluid dynamics design to deliver greater flow and higher head for the same power, thereby reducing energy consumption. Furthermore, their low-noise operation minimizes environmental impact, making them particularly suitable for densely populated urban areas and public facilities requiring a quiet environment. Seventh, ease of maintenance is also a major advantage of centrifugal fire pumps. The pump unit’s design fully considers maintenance needs throughout its lifecycle, resulting in a compact and rational structure and easy replacement of common wearing parts, significantly reducing maintenance time and labor costs. Furthermore, the equipment has a long lifespan and, with proper maintenance, can maintain efficient operation for many years, saving users long-term operating costs. Eighth, centrifugal fire pumps are highly resistant to fluctuating operating conditions and can adapt to varying water qualities and complex operating environments. Whether handling clear water, mildly corrosive media, or water sources containing small amounts of impurities, the pumps maintain efficient operation and ensure continuous water supply. This stability provides strong support for industrial production processes and enhances the safety of municipal water supply networks. Ninth, in emergency situations, centrifugal fire pumps can respond quickly and provide sufficient water pressure. For firefighting systems, startup speed and water supply stability are directly related to firefighting efficiency. With its reliable control system and superior performance, this equipment ensures immediate operational availability upon fire, minimizing fire damage. Finally, as a key component in industrial and municipal systems, the centrifugal fire pump’s comprehensive advantages lie not only in its robust water supply capacity and stability, but also in its energy efficiency, environmental protection, ease of maintenance, and intelligent management. It is a reliable partner for continuous operation, providing continuous cooling and circulating water supply for industrial production lines, as well as stable water pressure for urban pipe networks, providing emergency support for fire safety. With the continuous improvement of urbanization and industrialization, the importance of such equipment will become increasingly prominent and become an important cornerstone for supporting the safe operation of cities and industries.