Application of Diesel Engine Fire Pump

As a fixed firefighting equipment, diesel engine fire pump has been widely used in firefighting and shunting, especially when there is no power supply or power supply (main power supply).

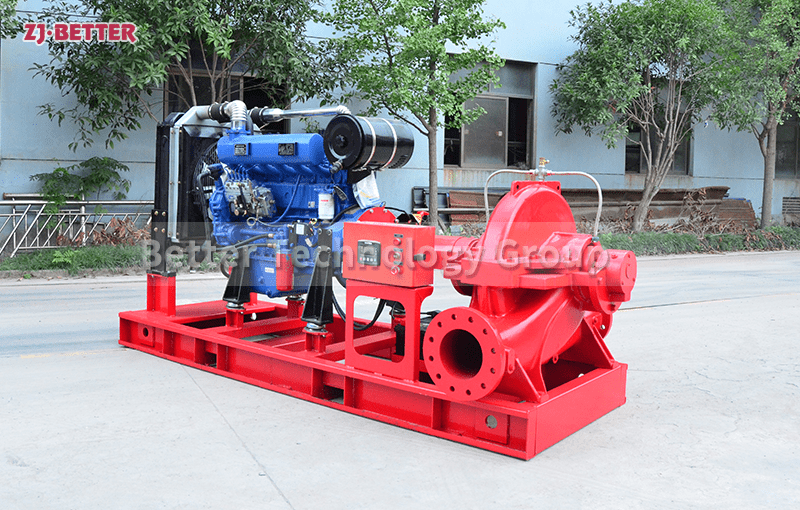

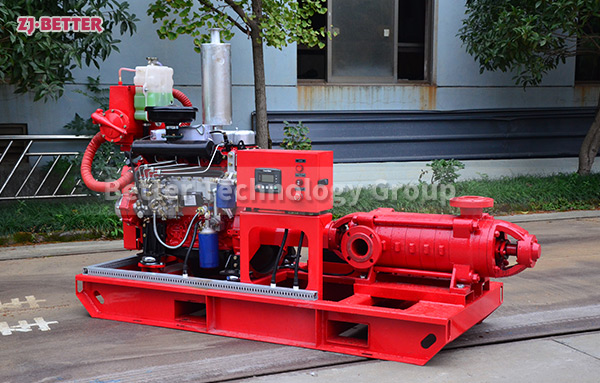

Diesel engine fire pumps can also be equipped with other diesel engines as power engines according to the needs of users. It is mainly composed of diesel engine, fire pump, connection device, fuel tank, radiator, battery, intelligent automatic control panel, etc. The whole crankshaft of diesel engine fire pump has high rigidity, high strength and high torque transmission efficiency. It adopts international advanced technology and gantry blocks, sliding bearings, plate-fin coolers, upper heat exchangers, rotary oil filters, and double cooling systems. The performance of the diesel engine fire pump is superior, the smoke and noise indicators reach the national level, and the fuel consumption is lower than the national standard by more than 2.1g/kw.h.

The diesel engine fire pump has a high degree of automation, with automatic, manual and fault self-inspection functions, and monitors the working status during the whole process. It can restore the automatic restart function after failure, automatic pre-lubrication and pre-heating, so that the equipment can start more safely and reliably. The diesel engine fire pump has remote control and remote control functions in the central control room. It can also have a fieldbus connection. The battery adopts fully automatic floating charge (constant current, constant voltage, dripping charge) to ensure that the battery is in a standby state at any time.