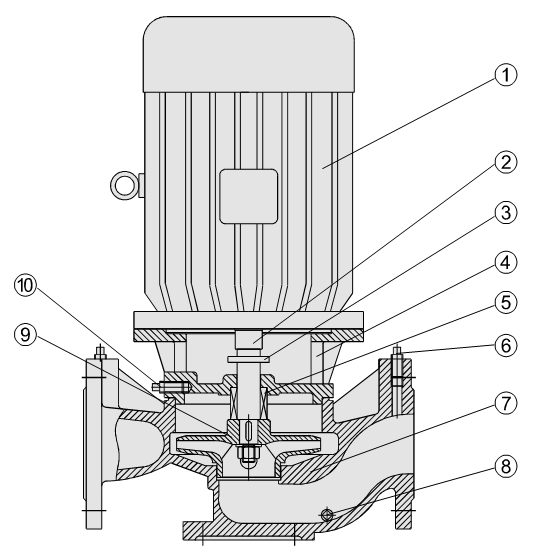

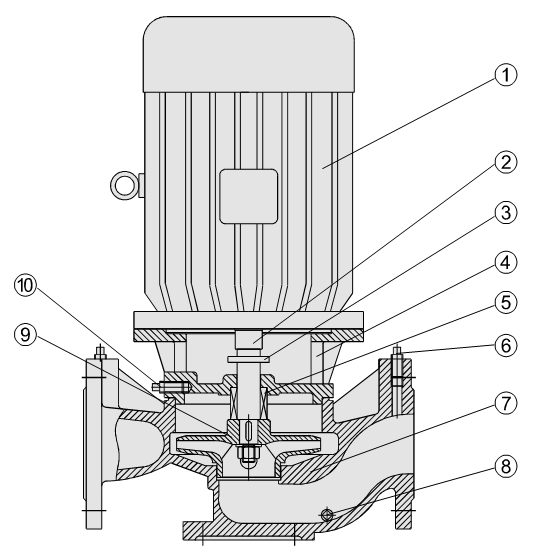

1. Vertical

1. Y/Y2 Series Motor: the driving part of pump, with a close- coupled type.

2. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

3. Water Deflector: to avoid water entering motor due to leakage at seal.

4. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

5. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

6. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

7. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy

8. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

9. Air Release Valve: to release the air inside to ensure the normal start of pump.

10. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

Model meaning: