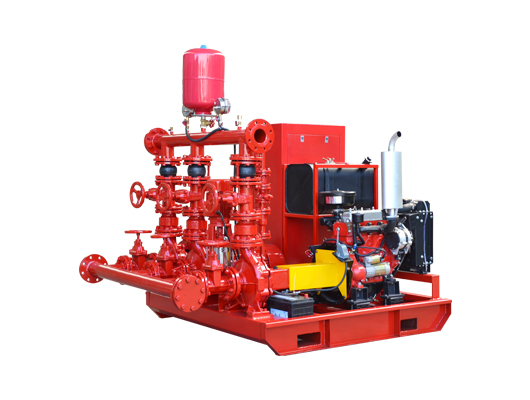

EEDJ Fire Jockey Pump Set (Electric pump*2+Diesel pump+Jockey pump)

Fire pump set comprises a combination of electric motor driven pump, diesel engine driven and electric driven jockey pumps that supply for fire suppression systems.Fire pump package is required to comply with Local Civil Defense Authority regulations and international Codes of Practice ,for example National Fire Protection Association (NFPA)

Types of pumps used for fire service include: end suction, horizontal split case, vertical split casevertical inline and vertical turbines.

1. Electric motor driven pump, can use single stage pump, horizontal split case pump, end suction pump,multistage pump, material can be cast iron, stainless steel, and bronze impeller2. Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank, fan,control box

3. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric anddiesel engine pump

4. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, overcurrent protection.

5. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, PressureGauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Baseplant.