Feature

Here are some features:

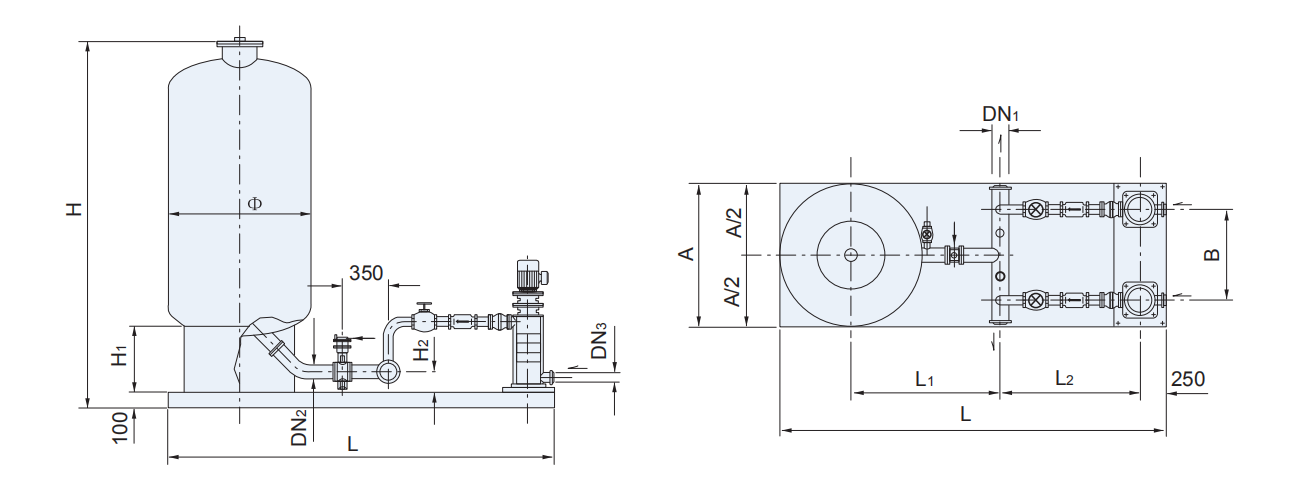

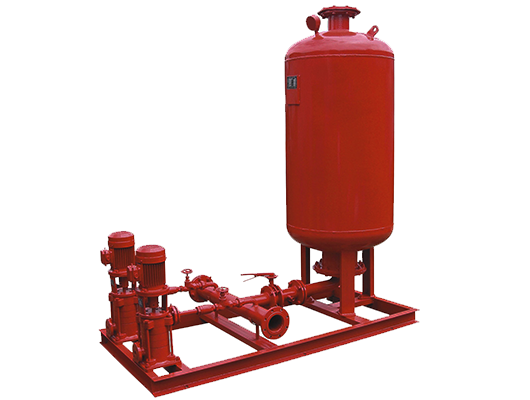

1. Our system comprises a pump, an electric control cabinet, a diaphragm-type pressure tank, and an integrated pipe network, complete with vibration isolators. There's no need for pre-embedded footings. Designers can effortlessly determine equipment models and foundation requirements by calculating parameters such as size. Electrical designers are relieved of the burden of designing control lines, as they only need to connect incoming power lines in the pump room to the equipment. This convenient selection process significantly reduces the design cycle and construction time.

2. The diaphragm-type pressure tank is not only durable but also equipped for one-time inflation. It ensures a reliable separation of water and gas, effectively preventing water pollution.

3. Our equipment boasts a compact footprint, requiring minimal investment. It operates automatically, requiring minimal maintenance.

4. With dual power interfaces, our equipment seamlessly handles two-way power supply, automatically or manually, as per design requirements.

5. Automatic protection mechanisms and failover options are integral to our system. In case of pump failure, be it electrical or hydraulic, a backup pump initiates automatically.

6. Our system can easily integrate with fire control centers, aligning with specific design requirements.

7. Tailor our system to your needs by selecting tank capacities, voltage regulation, and control functions as desired.

8. We utilize premium electrical components from reputable domestic and international brands, ensuring dependable quality and stable operation.

.jpg)