| Type | Stage | Flow | Head | Efficiency | Power(kw)

|

Speed |

(NPSH)r |

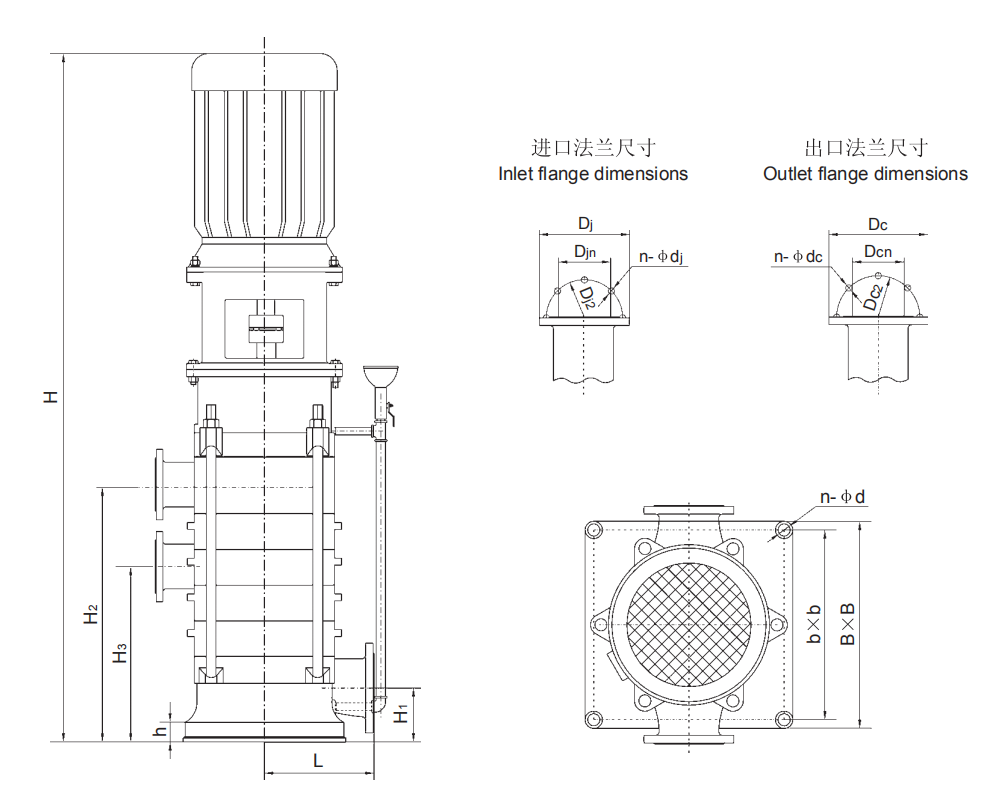

Dimensions(mm)

|

Weight | |||

|

(m³/h) |

(L/s) |

(m) |

(%) |

shaft power | motor power |

(r/min) |

(m) |

H | H1 |

(kg) |

||

| 40DL6-12 | 2 | 4.9 | 1.36 | 24.8 | 33 | 0.9 | 1.5 | 1480 | 3 | 905 | 298 | 160 |

| 6.2 | 1.72 | 23.6 | 40 | 0.98 | 3.2 | |||||||

| 7.4 | 2.06 | 21.6 | 39 | 1.11 | 3.6 | |||||||

| 50DL12-12.5 | 2 | 9 | 2.5 | 27 | 47 | 1.4 | 3 | 1480 | 2 | 935 | 344 | 160 |

| 12 | 3.5 | 25 | 55 | 1.56 | 2.2 | |||||||

| 15 | 4.1 | 23 | 58 | 1.62 | 2.6 | |||||||

| 65DL30-16 | 2 | 18 | 5 | 37 | 56 | 3.24 | 5.5 | 1480 | 2.41 | 1145 | 332 | 280 |

| 30 | 8.33 | 32 | 62 | 4.22 | 2.82 | |||||||

| 35 | 9.72 | 29 | 60 | 4.6 | 3.03 | |||||||

| 80DL50-20 | 2 | 32.4 | 9 | 43.2 | 59 | 6.28 | 11 | 1480 | 2.1 | 1335 | 407 | 410 |

| 50 | 14 | 40 | 70 | 8.4 | 2.2 | |||||||

| 65.2 | 18.1 | 34.2 | 66 | 9.23 | 2.8 | |||||||

| 100DL72-20 | 2 | 50.4 | 14 | 46 | 62 | 10.2 | 15 | 1480 | 2.2 | 1415 | 422 | 450 |

| 72 | 20 | 40 | 72 | 10.9 | 2.8 | |||||||

| 86.4 | 24 | 36 | 71 | 11.9 | 3.1 | |||||||

| 100DL100-20 | 2 | 72 | 20 | 43 | 62.5 | 13.3 | 18.5 | 1480 | 2.2 | 1480 | 422 | 500 |

| 100 | 27.8 | 40 | 72 | 16.3 | 2.8 | |||||||

| 126 | 35 | 34 | 73 | 16.9 | 3.1 | |||||||

| 125DL126-20 | 2 | 88.2 | 24.5 | 46 | 62 | 17.89 | 30 | 1480 | 2.2 | 1480 | 422 | 530 |

| 126 | 35 | 40 | 72 | 19.14 | 2.8 | |||||||

| 144 | 40 | 36 | 71 | 19.97 | 3.1 | |||||||

| 150DL144-20 | 2 | 100 | 30 | 45 | 75 | 17.6 | 37 | 1480 | 2.2 | 1850 | 590 | 760 |

| 144 | 40 | 40 | 80 | 20.4 | 2.8 | |||||||

| 180 | 50 | 34 | 78 | 33.3 | 3.7 | |||||||

| 150DL160-25 | 2 | 120 | 33.3 | 53 | 72 | 24.1 | 37 | 1480 | 3.3 | 1710 | 470 | 680 |

| 160 | 44.4 | 50 | 76 | 28.7 | 3.5 | |||||||

| 200 | 55.6 | 44 | 74 | 32.4 | 3.8 | |||||||

| 200DL300-20 | 2 | 210 | 58.3 | 45 | 70 | 36.7 | 55 | 1480 | 4.2 | 2115 | 635 | 1080 |

| 300 | 83.3 | 40 | 79 | 41.4 | 5 | |||||||

| 360 | 100 | 36 | 78 | 45.3 | 5.5 | |||||||

| 200DL288-25 | 2 | 200 | 55 | 53 | 71.5 | 40.54 | 75 | 1480 | 2.2 | 2115 | 635 | 1180 |

| 288 | 80 | 50 | 73 | 53.94 | 2.8 | |||||||

| 342 | 95 | 44 | 73.7 | 55.83 | 3.1 | |||||||

| 200DL288-30 | 2 | 201.6 | 56 | 62 | 70 | 48.63 | 90 | 1480 | 4.2 | 2115 | 635 | 1080 |

| 288 | 80 | 60 | 79 | 59.57 | 5 | |||||||

| 360 | 100 | 55 | 78 | 69.13 | 5.5 | |||||||

| 250DL400-40 | 2 | 288 | 80 | 84 | 71.5 | 92.52 | 160 | 1480 | 2.5 |

|

|

|

| 400 | 110 | 80 | 73.7 | 118.73 | 4 | |||||||

| 486 | 135 | 71 | 74.2 | 127.16 | 5.2 | |||||||

| 250DL500-40 | 2 | 350 | 97 | 84 | 73.2 | 109.83 | 185 | 1480 | 2.5 |

|

|

|

| 500 | 140 | 80 | 74.2 | 147.42 | 4 | |||||||

| 600 | 167 | 71 | 74.5 | 156.36 | 5.2 | |||||||

| More specifications, please contact us.

|

||||||||||||